EPSON Stylus Photo R1900/R2880/R2000

Revision E

Adjustment

Adjustment Items and Overview

142

Confidential

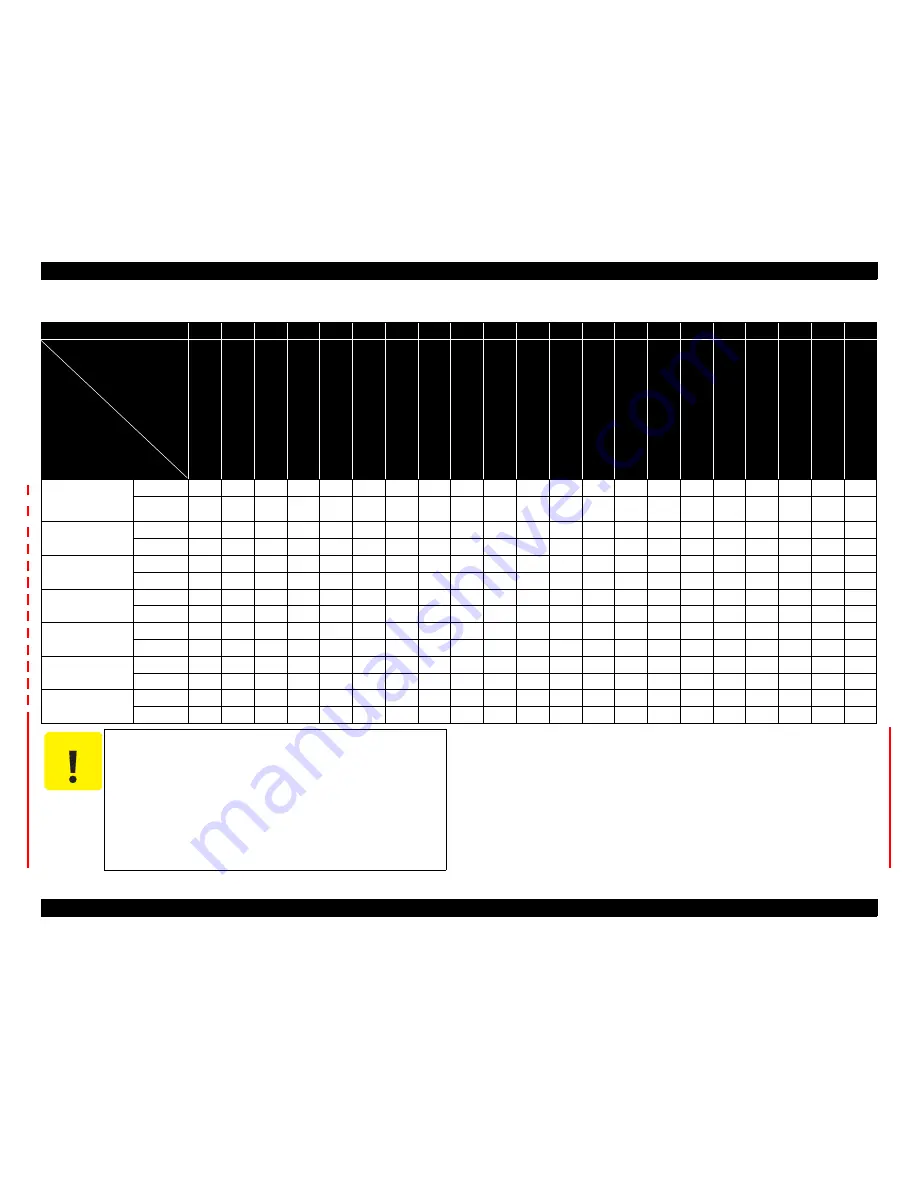

Note :

“O” indicates that the adjustment must be carried out. “---” indicates that the adjustment

is not required. If you have removed or replaced multiple parts, make sure to check the

required adjustments for the all parts. And when multiple adjustments must be carried

out, be sure to carry out them in the order given in the “Priority” row.

Note "*1" :When only removing the ASF Assy, you do not need to perform the adjustment. In

that case, mark the installing positions before removing them, and make sure to align

the markings when installing. See

"4.4.6 ASF Assy"

(p106)

.

"*2" :Replacing the Waste Ink Tray Assy is necessary when resetting waste ink pad counter.

"*3" :When only removing the Carriage Shaft, you do not need to perform the adjustment.

In that case, mark on the Parallelism Adjust Bushing (Left/Right) before removing

them, and make sure to align the markings when installing. See

"4.4.5 Carriage Shaft

/ Carriage Unit"

(p98)

.

Waste Ink Pad/

Front Paper Guide

Pad

Remove

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

O

Replace

---

---

---

---

---

---

---

---

O

---

---

---

---

---

---

---

---

---

---

---

O

Carriage shaft

Remove

---

---

---

*3

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

O

Replace

---

---

---

O

---

---

---

---

---

---

---

---

O

O

O

---

O

---

---

---

O

Carriage Unit

Remove

---

---

---

O

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

O

Replace

---

---

---

O

---

---

---

---

---

---

---

---

O

O

O

---

O

---

---

---

O

Paper EJ Frame

Assy

Remove

---

---

---

---

---

---

---

---

---

---

---

---

---

O

---

---

---

O

---

---

O

Replace

---

---

---

---

---

---

---

---

---

---

---

---

---

O

---

---

---

O

---

---

O

Printer Mechanism

Remove

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

O

Replace

O

---

O

O

---

---

---

---

---

---

O

---

O

O

O

O

O

O

O

---

O

PW Sensor

Remove

---

---

---

---

---

---

---

---

---

---

---

---

---

O

---

---

---

---

---

---

O

Replace

---

---

---

---

---

---

---

---

---

---

---

---

---

O

---

---

---

---

---

---

O

Ink Mark Sensor

Remove

---

---

---

---

---

---

---

---

---

---

---

---

---

O

---

O

---

---

---

---

O

Replace

---

---

---

---

---

---

---

---

---

---

---

---

---

O

---

O

---

---

---

---

O

Table 5-4. Required Adjustment List

Priority

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

PF Belt tension

adjustment

PF Roller Sh

aft

Cen

ter

Suppo

rt Position

adjustment

ASF Guide Roll

er

LDs

Position Adjustment

PG Adjustment

High Voltage

Module

inspe

cti

on

EEPROM Data

Copy

Init

ial

setti

ng

/USB

ID Input

Head ID in

put

Cons

umable

s mainte

nanc

e

coun

ter

Ink charge

Initialize PF

deteriorat

ion

offset

Disenable PF

deterioration

offset

First dot

positio

n

adjustm

ent

PW a

d

justment

Head angular

adjust

ment

Multi Sensor Adjustment

(Ink

M

ark

Sensor Ad

ju

stm

en

t)

Bi-D adjustment

PF adj

u

stment

CR

motor heat protection

con

tr

ol

Color

ime

tr

ic ca

libra

tion

Final

ch

ec

k patter

n print

C A U T I O N

When the EEPROM Data Copy cannot be made for the main

board that needs to be replaced, the Waste Ink Tray Assy must

be replaced after replacing the main board with a new one.

After all required adjustments are completed, use the “Final

check pattern print” function to print all adjustment patterns

for final check. If you find a problem with the printout

patterns, carry out the adjustment again.

When using a new main board for replacing the Printer

Mechanism, the Initial setting must have been made to the

main board.

Adjustment

Item

Part Name

Summary of Contents for R1900 - Stylus Photo Color Inkjet Printer

Page 1: ...EPSONStylusPhotoR1900 R2880 R2000 Color Inkjet Printer SEIJ07010 SERVICE MANUAL Confidential ...

Page 9: ...Confidential C H A P T E R 1 PRODUCTDESCRIPTION ...

Page 28: ...Confidential C H A P T E R 2 OPERATINGPRINCIPLES ...

Page 33: ...Confidential C H A P T E R 3 TROUBLESHOOTING ...

Page 69: ...Confidential C H A P T E R 4 DISASSEMBLYANDASSEMBLY ...

Page 137: ...Confidential C H A P T E R 5 ADJUSTMENT ...

Page 161: ...Confidential C H A P T E R 6 MAINTENANCE ...

Page 170: ...Confidential C H A P T E R 7 APPENDIX ...

Page 172: ...Confidential C H A P T E R 8 STYLUSPHOTOR2000 ...