Setup & Operation 3.4 Noise Countermeasures (Installation)

28

RC420 Rev.9

3.4 Noise Countermeasures

To minimize electrical noise conditions, the following items must be observed in the

system’s cable wiring:

- The earth wire of the power supply should be grounded. (Ground resistance: 100

Ω

or

less)It is important to ground the frame of Controller not only for prevention from

electric shock, but also for reducing the influence of electric noise around the

Controller. Therefore, be sure to connect the earth wire (yellow/green) of the

Controller’s power cable to the ground terminal of the factory power supply. For

details about the plug and AC power cable, refer to the

Setup & Operation “3.2.2

Power Plug

.

- Do not tap power from a power line that connects to any equipment which may cause

noise.

- When you tap power for the Controller and the single-phase AC motor from the same

power line, change the phase of one or the other. Ensure that they will not be the

same phase.

- Use a twisted pair motor power line.

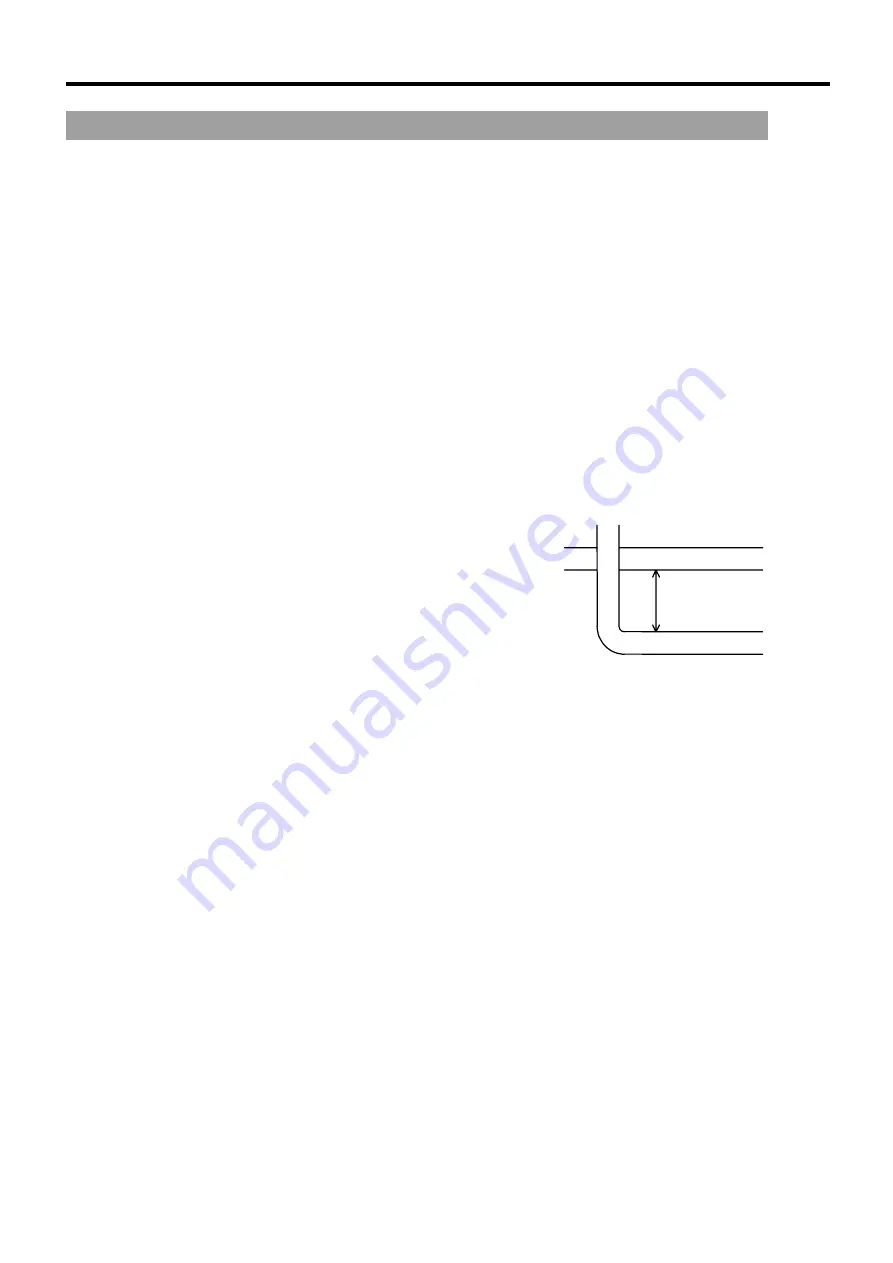

- Do not run AC power lines and DC power lines in

the same wiring duct, and separate them by at least

200 mm. For example, separate the AC motor

power line and the Controller power line by at least

200 mm from the sensor or valve I/O lines; and do

not bundle both sets of wiring with the same cable

tie. If more than one duct/cable must cross each

other, they should cross perpendicularly. The

preferable example is shown in the right figure.

AC Line duct

DC line duct

200 mm or more

- For I/O lines, wire as short as possible and use a shielded cable and clamp the shield to

the attached connector interior.

- Use a shielded cable for the EMERGENCY connector and clamp the shield to the

interior of the connector.

- Make sure that the induction elements used to connect to the Controller’s I/O (such as

relays and solenoid valves) have surge suppressors. If an induction element without

surge suppressor has be used, make sure to connect a rectifying diode right in front of

the induction element. In selecting a rectifying diode, make sure that it can handle

the voltage and current incurred by the induction load.

- To start and change revolutions of the conveyer’s (or the like’s) AC motor (ex: an

induction motor or three-phase induction motor) regularly or abruptly, make sure to

install a spark suppressor between the wires. The spark suppressor is more effective

when placed closer to the motor.

- As they are easily influenced by static electricity or the noise from power source, keep

the mouse and keyboard away from peripheral noise sources.

It is sometimes effective in suppressing such noise to wind the keyboard or mouse cables

around a ferrite core several times.

)

NOTE

Summary of Contents for RC420

Page 1: ...Rev 9 EM073C1492F ROBOT CONTROLLER RC420 ...

Page 2: ...ROBOT CONTROLLER RC420 Rev 9 ...

Page 12: ...Setup Operation ...

Page 20: ...Setup Operation 1 Safety 10 RC420 Rev 9 ...

Page 30: ...Setup Operation 2 3 Controller Part Names and Functions 20 RC420 Rev 9 ...

Page 50: ...Setup Operation 5 5 Circuit Diagrams EMERGENCY Connector 40 RC420 Rev 9 ...

Page 58: ...Setup Operation 6 3 Pin Assignments STANDARD I O Connector 48 RC420 Rev 9 ...

Page 114: ...Setup Operation 10 UPS Uninterruptible Power Supply 104 RC420 Rev 9 ...

Page 115: ...97 Maintenance This manual contains maintenance procedures for the RC420 Robot Controller ...

Page 116: ...Maintenance RC420 Rev 9 106 ...

Page 138: ...Maintenance 6 Motor Driver Module 128 RC420 Rev 9 ...

Page 170: ...Maintenance 12 Recovering the HDD 160 RC420 Rev 9 ...