Maintenance 9. Troubleshooting

RC90 (EPSON RC+ 7.0) Rev.8

171

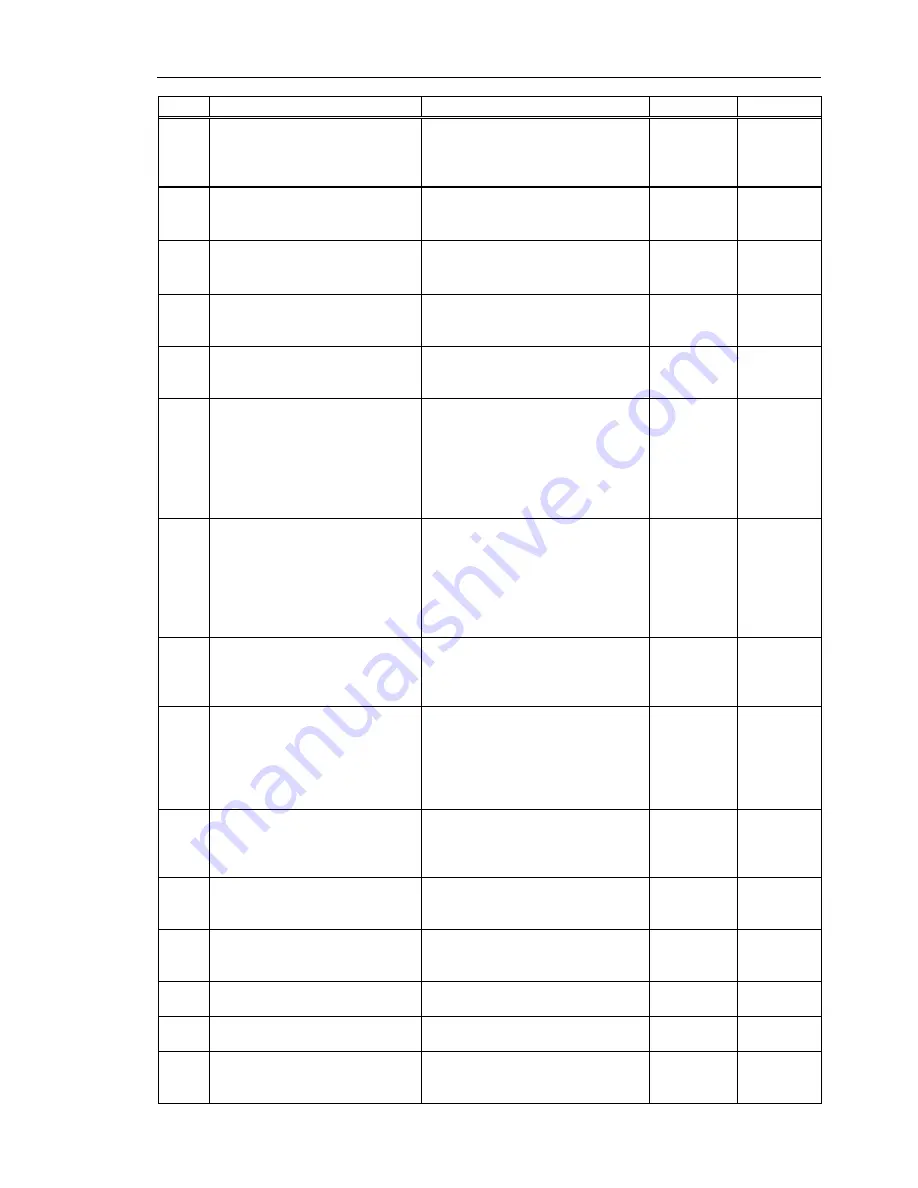

No.

Message

Remedy

Note 1

Note 2

4099

Servo error was detected during

operation.

Check if a 5000 number error is

occurring in the system history. If the

error is occurring, take measures for a

5000 number error.

4100

Communication error in motion

control module. Cannot calculate

the current point or pulse.

Reboot the controller.

Initialize the controller firmware.

Replace the controller.

4101

Communication error in the motion

control module. Cannot calculate

the current point or pulse.

Reboot the controller.

Initialize the controller firmware.

Replace the controller.

4103

Initialization failure. Motion control

module initialization error.

Reboot the controller.

Initialize the controller firmware.

Replace the controller.

4104

Positioning timeout of the joint

connected to the Pulse Generator

Board.

Cannot receive the positioning

completion signal (DEND) from the

servo motor connected to PG board.

4150

Redundant input signal failure of the

emergency stop.

The input status of the redundant

emergency stop input continuously

differs for more than two seconds.

Check whether no disconnection, earth

fault, or short-circuit of the emergency

stop input signal exits. Then reboot the

controller.

4151

Redundant input signal failure of the

safeguard.

The input status of the redundant

emergency stop input continuously

differs for more than two seconds.

Check whether no disconnection, earth

fault, or short-circuit of the emergency

stop input signal exits. Then reboot the

controller.

4152

Relay welding error of the main

circuit.

A relay welding error was detected due to

power system over current.

Replace the controller.

Replace the robot.

4153

Redundant input signal failure of the

enable switch.

The input status of the redundant enable

signal differs continuously for more than

two seconds.

Check the TP connector connection.

Replace the TP.

Replace the controller.

4154

Temperature of regeneration resistor

was higher than the specified

temperature.

Robot’s Duty is too high. Lengthen the

waiting time or reduce the Accel value.

If the error occurs although Duty was

lowered, replace the DPB.

4180

Manipulator initialization failure.

Specified manipulator was is not

found.

Configure the manipulator.

4181

Manipulator initialization failure.

Specified manipulator was in use by

another task.

Specified manipulator cannot be

configured since it is already configured.

4182

Manipulator initialization failure.

Manipulator name is too long.

Shorten the manipulator name.

4183

Manipulator initialization failure.

Manipulator data version error.

Reconfigure the manipulator.

4187

Manipulator initialization failure.

Communication error with the

module: VSRCMNPK.

Reboot the controller.

Initialize the controller firmware.

Replace the controller.

Summary of Contents for RC90

Page 1: ...Rev 8 EM158C3031F ROBOT CONTROLLER RC90 EPSON RC 7 0 ...

Page 2: ...ii ROBOT CONTROLLER RC90 EPSON RC 7 0 Rev 8 ...

Page 10: ...viii RC90 EPSON RC 7 0 Rev 8 ...

Page 17: ...Safety This section contains information for safety of the Robot System ...

Page 18: ......

Page 24: ......

Page 28: ...Setup Operation 1 Specifications 12 RC90 EPSON RC 7 0 Rev 8 1 3 Outer Dimensions Unit mm ...

Page 95: ...Maintenance This section contains maintenance procedures for the Robot Controller ...

Page 96: ......