Appendix

Options and Consumable Products

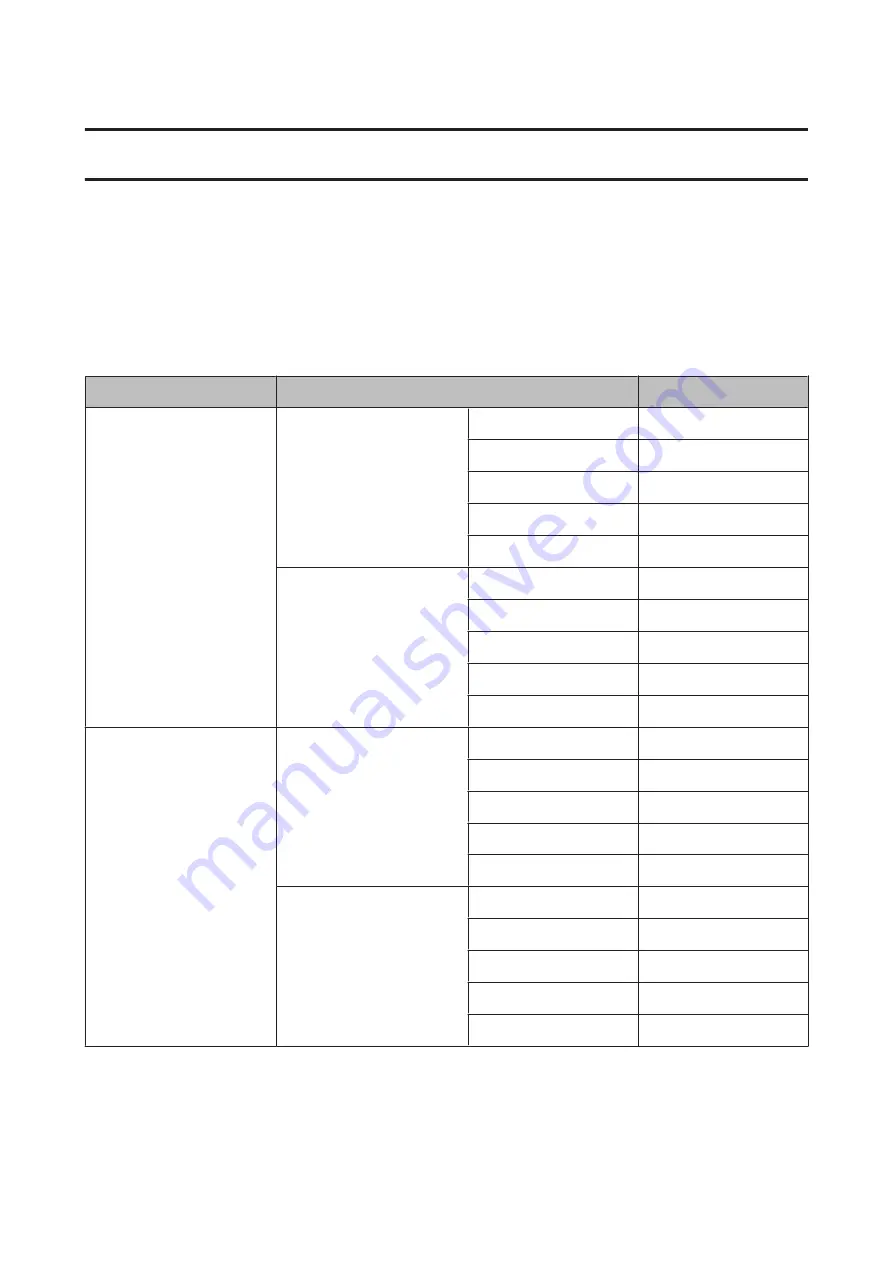

The following options and consumable products are available for use with your printer. (As of December, 2013)

For the latest information, see the Epson Web site.

Ink cartridges

*

Printer model

Product name

Product number

SC-F2000

Ink cartridges

(600 ml)

Black

T7251

Cyan

T7252

Magenta

T7253

Yellow

T7254

White

T725A

Ink cartridges

(250 ml)

Black

T7301

Cyan

T7302

Magenta

T7303

Yellow

T7304

White

T730A

SC-F2080

Ink cartridges

(600 ml)

Black

T7261

Cyan

T7262

Magenta

T7263

Yellow

T7264

White

T726A

Ink cartridges

(250 ml)

Black

T7311

Cyan

T7312

Magenta

T7313

Yellow

T7314

White

T731A

* Epson recommends the use of genuine Epson ink cartridges. Epson cannot guarantee the quality or reliability of

non-genuine ink. The use of non-genuine ink may cause damage that is not covered by Epson’s warranties, and under

certain circumstances, may cause erratic printer behavior. Information about non-genuine ink levels may not be

displayed, and use of non-genuine ink is recorded for possible use in service support.

SC-F2000 Series User’s Guide

Appendix

87