GX8 Manipulator 5. Motion Range

170

GX series Rev.2

5.2.2 Setting the Mechanical Stop of Joint #3

This method applies to the Standard-model Manipulator (GX8-A***S*) and ESD model

(GX8-A***E*).

For the Cleanroom & ESD model (GX8-A***C*) and Protected-model (GX8-A***P*), the

motion range set with the Joint #3 mechanical stop cannot be changed.

(1) Turn ON the Controller and turn OFF the motors using the Motor OFF command.

(2) Push up the shaft while pressing the brake

release switch.

Do not push the shaft up to its upper limit or

it will be difficult for the arm top cover to be

removed. Push the shaft up to a position

where the Joint #3 mechanical stop can be

changed.

Brake release switch

Lower limit

mechanical stop

Shaft

When you press the brake release switch, the shaft may lower and rotate due to the

weight of the end effector. Be sure to hold the shaft by hand while pressing the button.

(3) Turn OFF the Controller.

(4) Loosen the lower limit mechanical stop screw (2×M4).

A mechanical stop is mounted on both the top and bottom of Joint #3. However, only

the position of the lower limit mechanical stop on the top can be changed. Do not

remove the upper limit mechanical stop on the bottom because the calibration point of

Joint #3 is specified using the stop.

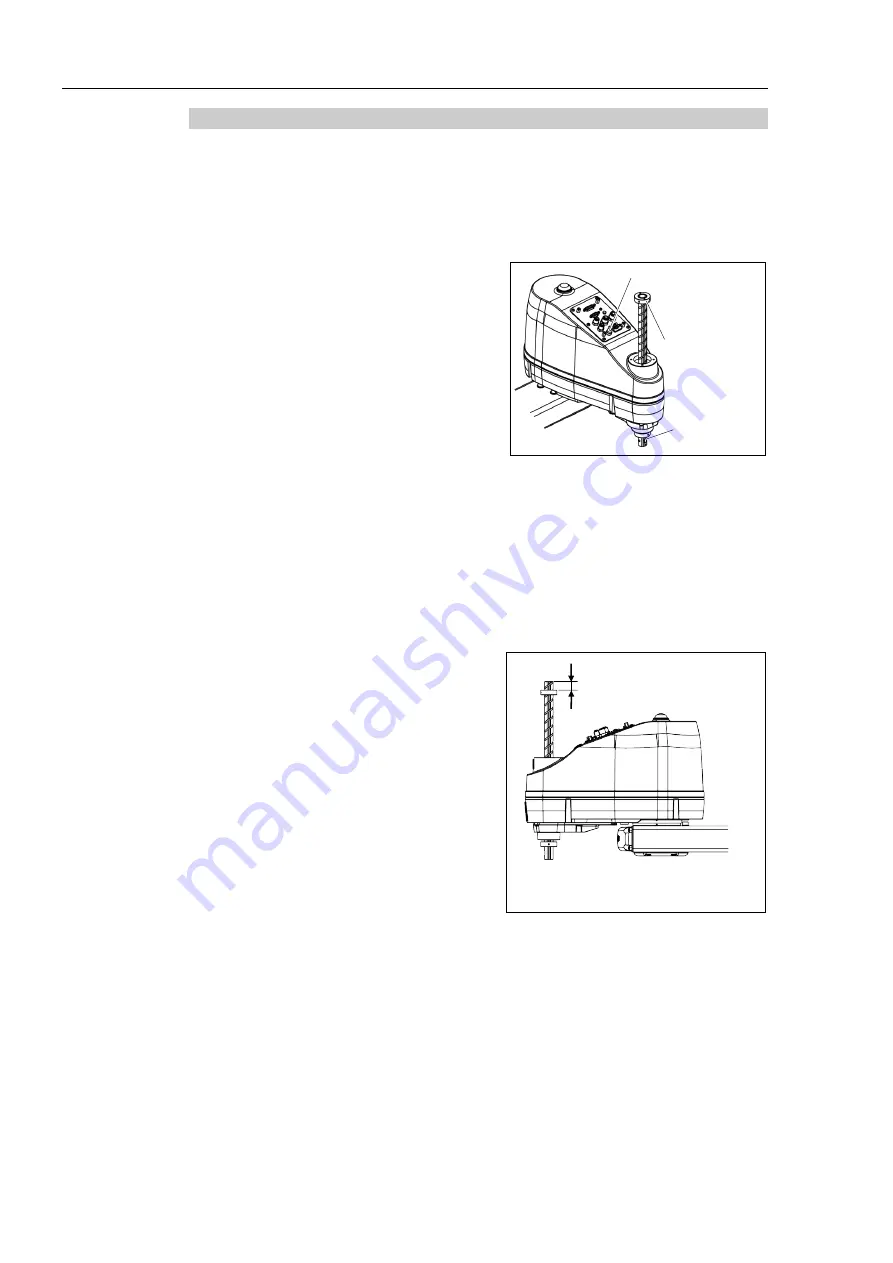

(5) The upper end of the shaft defines the

maximum stroke. Move the lower limit

mechanical stop down by the length you

want to limit the stroke.

For example, when the lower limit

mechanical stop is set at “200 mm” stroke,

the lower limit Z coordinate value is “-200”.

To change the value to “-150”, move the

lower limit mechanical stop down “50 mm”.

Use calipers to measure the distance when

adjusting the mechanical stop.

Measurement length

(6) Firmly tighten two lower limit mechanical stop screws (2×M4) so that they do not enter

the shaft groove.

Recommended tightening torque: 2.4N·m (25 kgf·cm)

(7) Turn ON the Controller.

(8) Move Joint #3 to its lower limit while pressing the brake release switch, and then check

the lower limit position. Do not lower the mechanical stop too far. Otherwise, the joint

may not reach a target position.

NOTE

NOTE

NOTE

Summary of Contents for SCARA GX Series

Page 1: ...Original instructions Rev 2 EM221R5129F SCARA Robots GX series Manual ...

Page 2: ...GX series Manual Rev 2 ...

Page 12: ......

Page 86: ...GX4 Manipulator 5 Motion Range 76 GX series Rev 2 ...

Page 88: ......

Page 188: ......

Page 202: ......