Regular Inspection 1. Regular Inspection for GX4 Manipulator

182

GX series Rev.2

Greasing the Ball Screw Spline Unit

Name

Quantity

NOTE

Grease

For Ball Screw Spline Unit

(AFB grease)

Proper

quantity

Tools

Wiping cloth

1

For wiping grease (Spline shaft)

Cross-point screwdriver

1

For clamp band removal

For Cleanroom & ESD model

only

Cover the surrounding area such as the end effector and peripheral equipment in case the

grease drips.

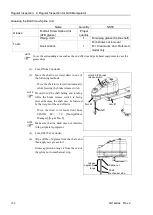

(1) Turn ON the Controller.

(2) Move the shaft to its lower limit in one of

the following methods.

-

Move the shaft to its lower limit manually

while pressing the brake release switch.

Be careful of the shaft falling and rotating

while the brake release switch is being

pressed because the shaft may be lowered

by the weight of the end effector.

-

Move the shaft to its lower limit from

EPSON RC+ 7.0 [Tools]-[Robot

Manager]-[Jog & Teach].

Make sure that the hand does not interfere

with peripheral equipment.

Joint #3 , #4

brake release

Arm #1

Arm #2

Shaft

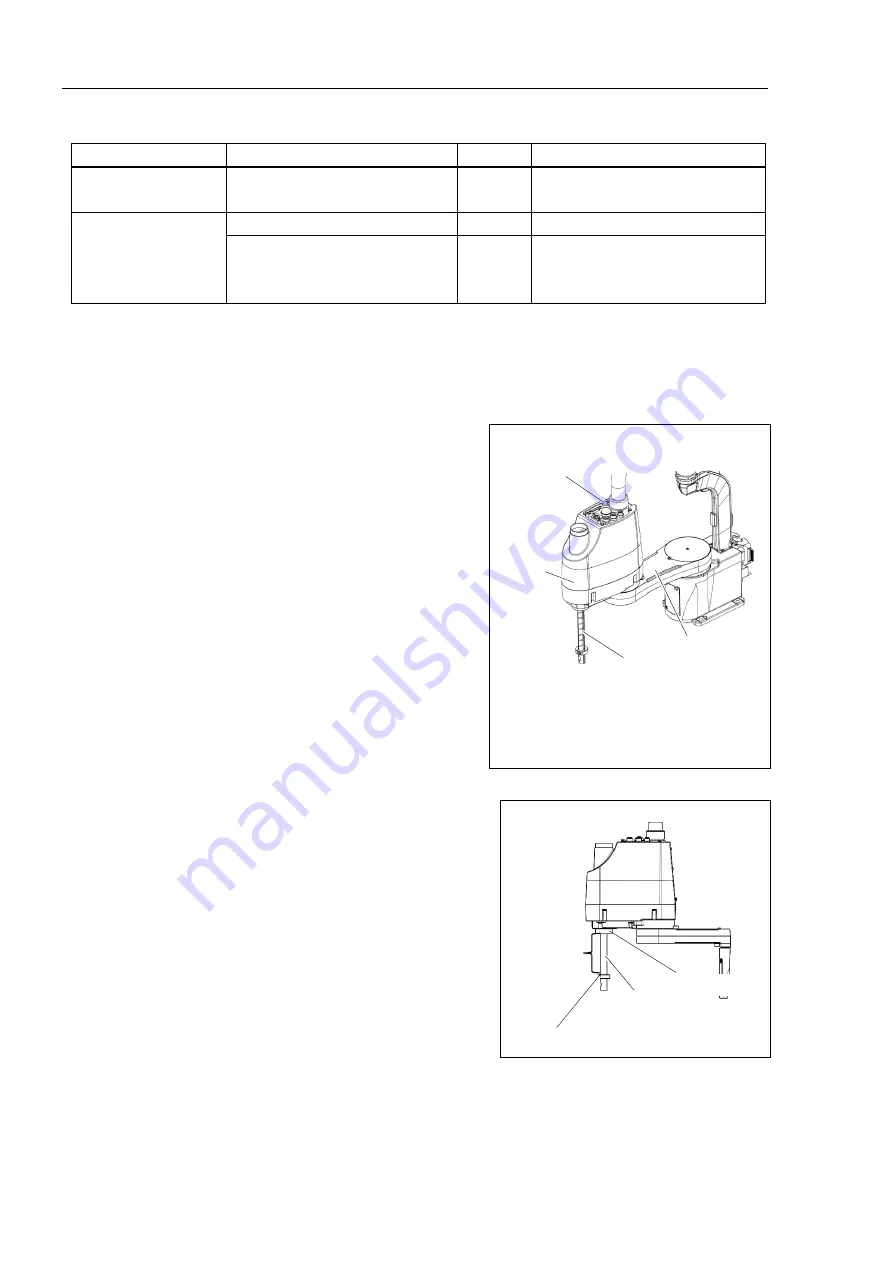

(3) Turn OFF the Controller.

(4) Wipe off the old grease from the shaft, and

then apply new grease to it.

Grease application range is from the end of

the spline nut to mechanical stop.

Grease

application

range

Shaft

Spline nut

Mechanical stop

NOTE

NOTE

NOTE

Summary of Contents for SCARA GX Series

Page 1: ...Original instructions Rev 2 EM221R5129F SCARA Robots GX series Manual ...

Page 2: ...GX series Manual Rev 2 ...

Page 12: ......

Page 86: ...GX4 Manipulator 5 Motion Range 76 GX series Rev 2 ...

Page 88: ......

Page 188: ......

Page 202: ......