Maintenance 4.5 DPB (Drive Unit)

136

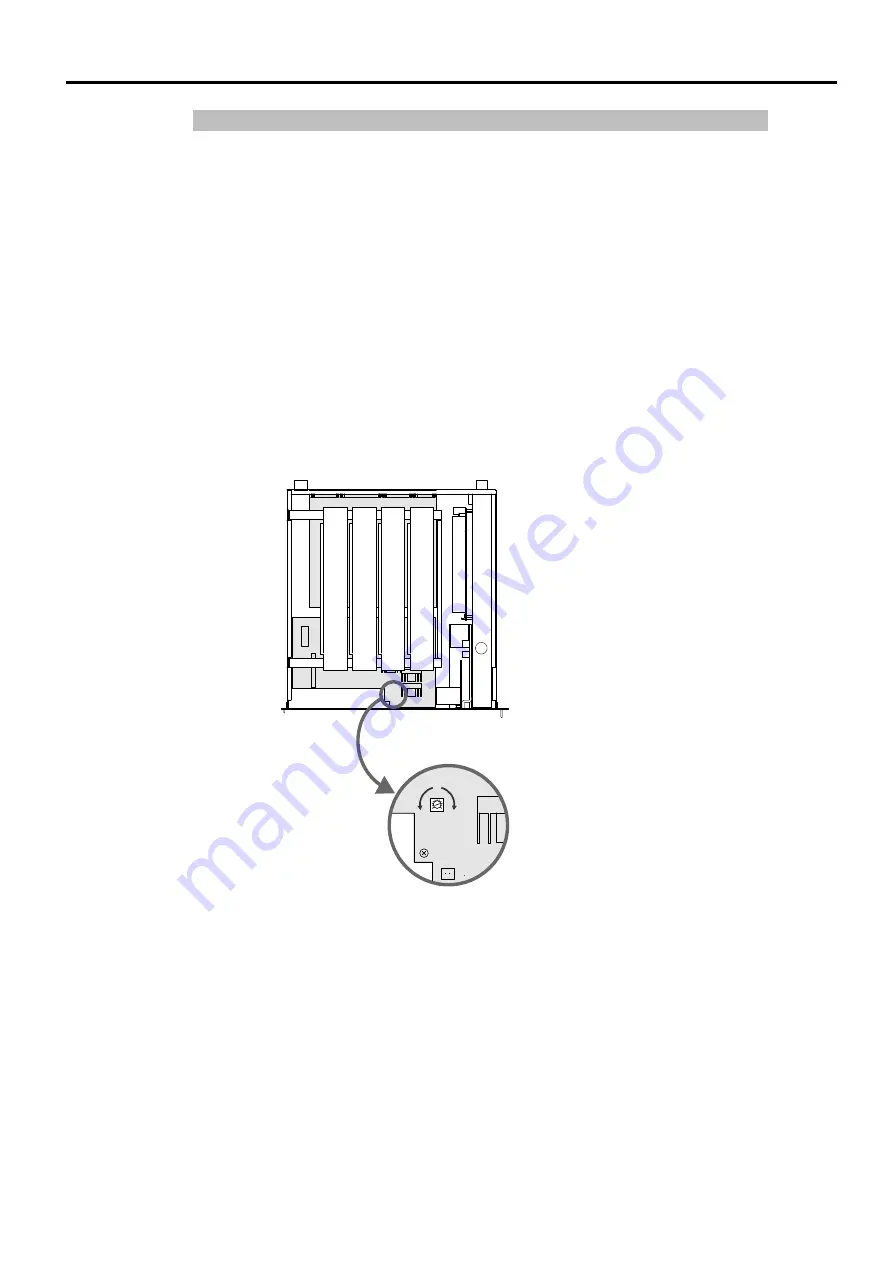

4.5.2 Adjusting Encoder Voltage

You may adjust the Encoder Power Supply voltage using a control knob, VR1 as follows:

(1) Turn ON the Drive and Control Units, and boot SPEL 95. The Robot must be put

into the emergency stop condition for safety. At this time, make sure that the

encoder power is being supplied by checking on the LED1 on the Manipulator’s relay

board. (The lamp must be ON.)

(2) Measure the voltage between the e5V and the GND pin on the Encoder

Signal connector of the longest motor cable in the Manipulator. (As for which pins

to measure, refer to the Manipulator manual.)

(3) If the encoder voltage is not within the range of 4.9V to 5.2V, adjust it as follows:

(4) Remove the Upper Cover of the Drive Unit by taking out the eight screws.

(5) If the measured voltage is lower than 4.9V, turn the VR1 on DPB knob “+” direction

by 1/2 track to increase the voltage. If the measure voltage is higher than 5.2V, turn

the VR1 knob “-” direction by 1/2 track to lower the voltage.

(6) Repeat the step (2) to ensure that the voltage is between “4.9V and 5.2V”.

(7) If necessary, repeat the steps (5) and (6) until the voltage is within the range of “4.9V

to 5.2V”.

(8) When the adjustment is completed, place the Upper Cover back on.

-

+

Summary of Contents for SRC520

Page 1: ...SRC520 Rev 4 EM015C868F ROBOT CONTROLLER ...

Page 2: ...ROBOT CONTROLLER SRC520 Rev 4 ...

Page 13: ...Function The manual herein explains in detail the functions of the robot controller SRC520 ...

Page 14: ...Function 2 ...

Page 29: ...Function 2 3 Control Unit Part Names and Functions 17 2 3 4 Dimensions mm ...

Page 35: ...Function 2 4 Drive Unit Part Names and Functions 23 2 4 5 Dimensions mm ...

Page 36: ...Function 2 4 Drive Unit Part Names and Functions 24 ...

Page 50: ...Function 3 5 Noise Countermeasures Installation 38 ...

Page 66: ...Function 6 3 Pin Assignments D I O Connector 54 ...

Page 96: ...Function 9 2 Preparation for Communication RS 232C Settings 84 ...

Page 106: ...Function 11 Stand alone Option for SRC520 94 ...

Page 108: ...Maintenance 96 ...

Page 139: ...Maintenance 4 3 Drive Unit Drive Unit 127 4 3 Drive Unit 4 3 1 System Configuration ...