Maintenance 5. Check List for the Manipulator Operation

148

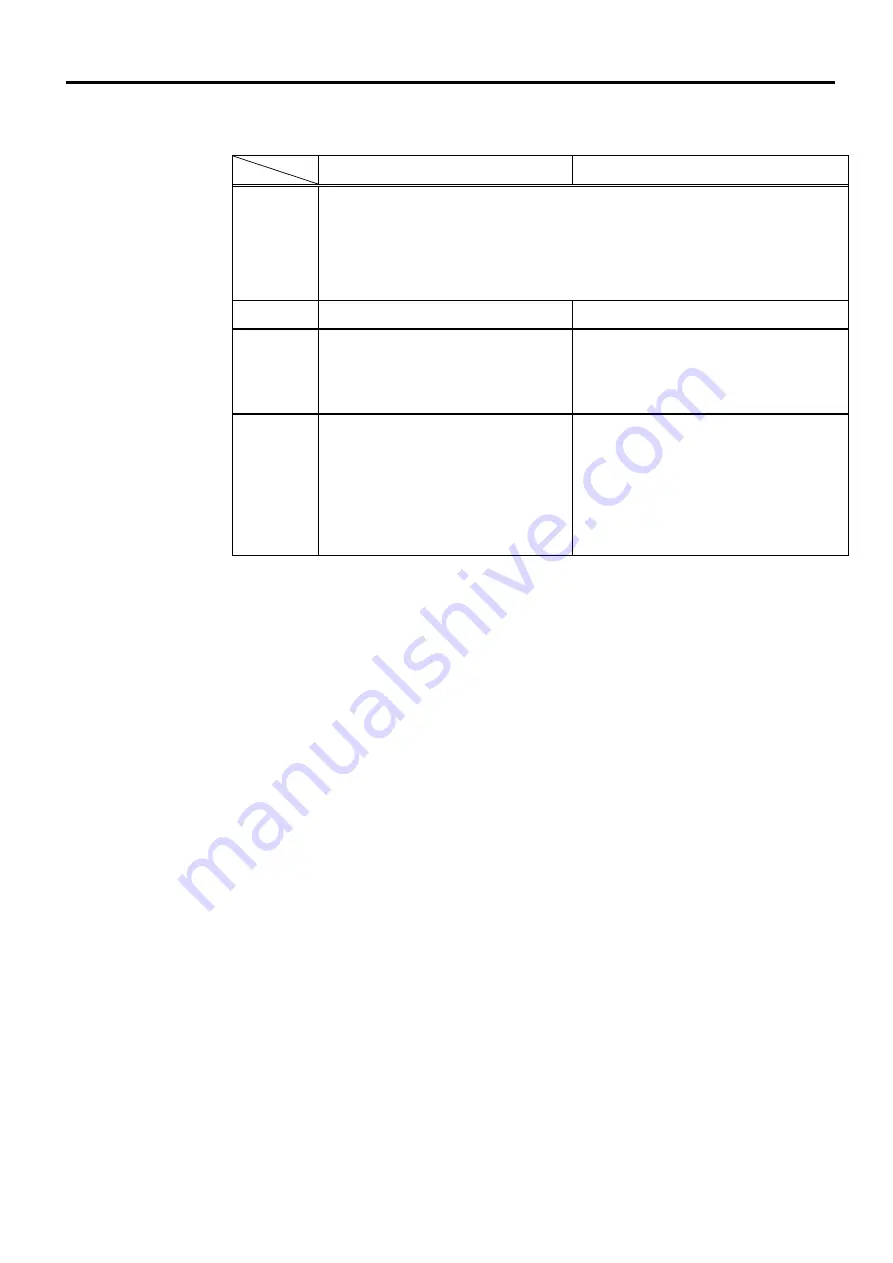

Control Unit – System Panel LED

From power-on to SPEL 95 launch

While running the SPEL 95

E-STOP

When the main power is turned ON, the light must turn ON momentarily and

must go OFF unless there is an emergency stop input.

If there is an emergency stop input at this time, the light must stay ON.

This lamp turns ON when there is an EMERGENCY STOP input to the Control

Unit’s OPTIONAL DEVICE connector and the Drive Unit’s EMERGENCY

connector.

RUN

The lamp must be blinking.

The lamp must be ON.

ERROR

The lamp must be blinking.

The lamp is OFF under normal

conditions.

It must turn ON when there is a system

error.

7 segment

When the main power is turned ON,

“8” lights up momentarily and goes

OFF.

The displayed data must change

from “0” in order to indicate the

system condition that is checked at

the beginning of SPEL 95 launch.

The lamp is OFF under normal

conditions.

In case of system error, it must display

the status of the error by the designated

number. (For details, refer to the

“Appendix B” in the SRC5**/SPEL 95

Appendix manual.)

(3) Execute MOTOR ON and check the followings:

・

No error displayed.

・

The MOTOR POWER LED on the Drive Unit’s Front Panel turns ON.

・

The Manipulator operates normally, and there is excitation.

(4) Execute various motion commands (such as JUMP, etc.). The robot must operate

accordingly and normally without vibration or abnormal sounds.

Summary of Contents for SRC520

Page 1: ...SRC520 Rev 4 EM015C868F ROBOT CONTROLLER ...

Page 2: ...ROBOT CONTROLLER SRC520 Rev 4 ...

Page 13: ...Function The manual herein explains in detail the functions of the robot controller SRC520 ...

Page 14: ...Function 2 ...

Page 29: ...Function 2 3 Control Unit Part Names and Functions 17 2 3 4 Dimensions mm ...

Page 35: ...Function 2 4 Drive Unit Part Names and Functions 23 2 4 5 Dimensions mm ...

Page 36: ...Function 2 4 Drive Unit Part Names and Functions 24 ...

Page 50: ...Function 3 5 Noise Countermeasures Installation 38 ...

Page 66: ...Function 6 3 Pin Assignments D I O Connector 54 ...

Page 96: ...Function 9 2 Preparation for Communication RS 232C Settings 84 ...

Page 106: ...Function 11 Stand alone Option for SRC520 94 ...

Page 108: ...Maintenance 96 ...

Page 139: ...Maintenance 4 3 Drive Unit Drive Unit 127 4 3 Drive Unit 4 3 1 System Configuration ...