EPSON Stylus Color 400 Service Manual

Rev. A

5-11

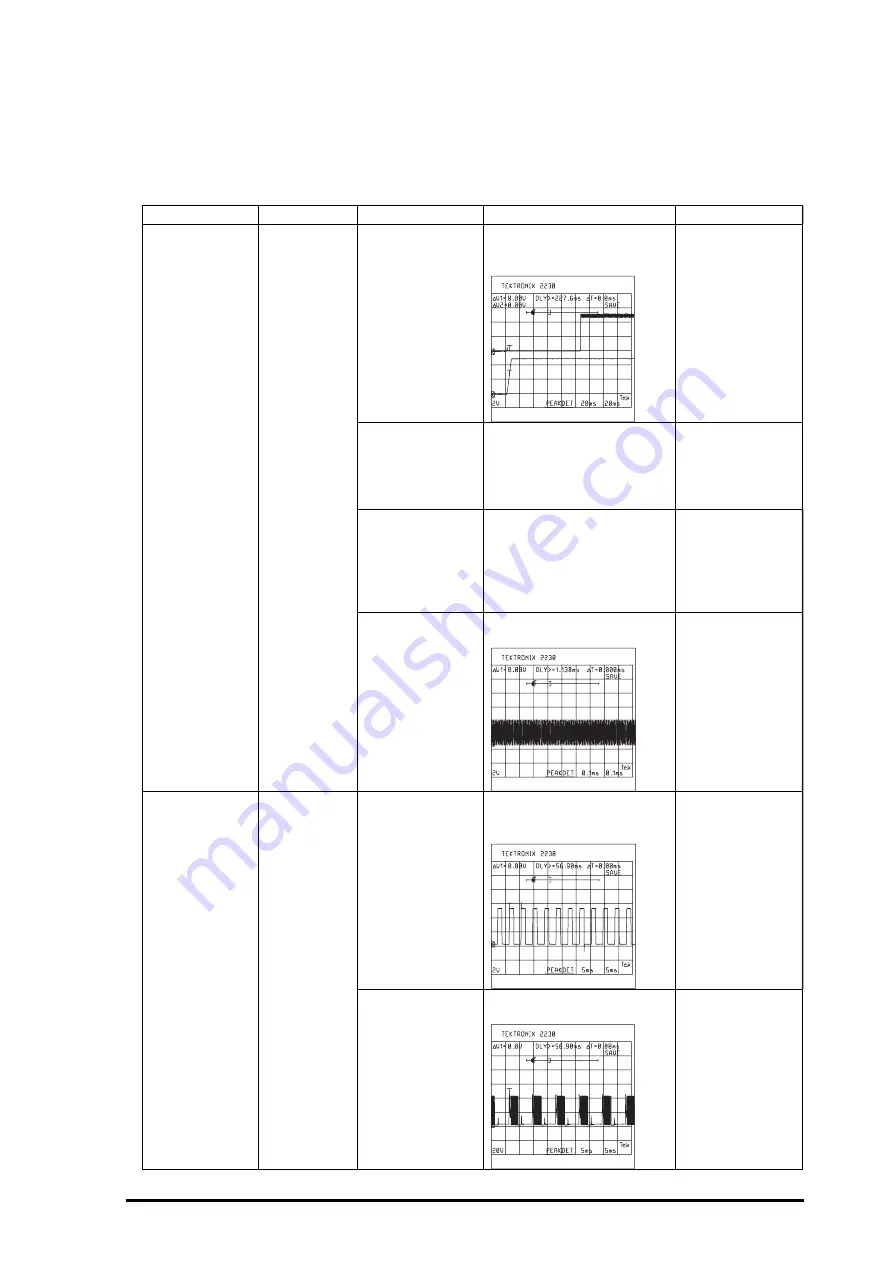

5.3.1 Unit Repair - C206 MAIN Board

This section describes the problems related to the main controller board(C206 main). The table below

provides various symptoms, likely causes, and checkpoints. The check points refer to waveforms,

resistance, and other values to be checked to evaluate the operation of each component.

Table 5-7. Repair of the C206 MAIN Board

Symptom

Condition

Cause

Checkpoint

Solution

The printer

does not

operate at all.

CPU does

not operate.

The reset

circuit does not

operate.

Check the waveform of

the +5V and /Reset signal

(IC8=5,1-pin/IC9=7,6-pin)

Replace IC8 or

IC9.

Control ROM is

not selected

correctly or it’s

dead.

If you can not find the

waveform at 2-pin of IC3,

the IC1 is dead, and if you

can not find it at 20-pin of

IC3, the IC3 is dead.

Replace IC1 or

IC3.

RAM is not

selected

correctly or it’s

dead.

If you can not find the

waveform at 29,14-pin of

IC4, the IC1 is dead, and

if you can not find it at 28-

pin of IC4, the IC4 is

dead.

Replace IC1 or

IC 4.

CRU2 is dead.

Check the waveform at

27,28-pin of IC1.

Replace the

CRU2.

The carriage

does not

operate

normally.

Carriage

motor does

not operate

at all.

IC2 is dead.

Check the waveform at

72,73 and 75, 76 pin of

IC14.

Replace IC2.

IC14 is dead.

Check the waveform at

6-9 pin if IC14.

Replace IC14.

Summary of Contents for Stylus Color 400

Page 5: ...REVISION SHEET Revision Issued Data Contents Rev A February18 1997 First issue ...

Page 126: ...Chapter 6 Maintenance Rev A 6 5 No 1 No 2 10mm 2mm 2mm No 3 No 11 GEAR 34 ...

Page 138: ...EPSON Stylus Color400 Service Manual Rev A A 9 Figure A 3 C206 PSB Board Component Layout ...

Page 139: ...Appendix Rev A A 10 Figure A 4 C206 PSE Board Component Layout ...

Page 140: ...EPSON Stylus Color400 Service Manual Rev A A 11 Figure A 5 C206 PNL Component Layout ...

Page 141: ...Appendix Rev A A 12 A 5 Exploded Diagrams Figure A 6 Stylus Color 400 Exploded Diagram 1 ...

Page 143: ...Appendix Rev A A 14 Figure A 8 Stylus Color 400 Exploded Diagram 3 ...

Page 145: ...EPSON SEIKO EPSON CORPORATION ...