Chapter2 Operating Principles

Rev.A

2-19

2.2.1 C206 PSB/PSE Power Supply Board

C206 PSB/PSE board is a power supply board with a RCC switching regulator, which gen42VDC

for drive part and +5VDC for logic part to drive the printer. One of the major characteristic of this board is

that the same secondary switch is used as Stylus Color series printer. By using this switch, the following

difference can be seen as superficial phenomena compared with products applied with primary switch

method, such as Stylus Color IIs, II and Stylus 800/1000 series printer. The table 2-12 below shows

application of voltages generated by C206 PSB/PSE board.

1) Even if the switch is turned off during the middle of printer operation, since the driving

power is turned off after the carriage goes back to the carriage lock position,

the possibility of clogging ink nozzle will be decreased.

2) If the switch is turned off when the papers in the printer are still being carried except for

the papers in the hopper, the same operation mentioned above is performed and the

driving power is turned off after the paper is completely ejected.

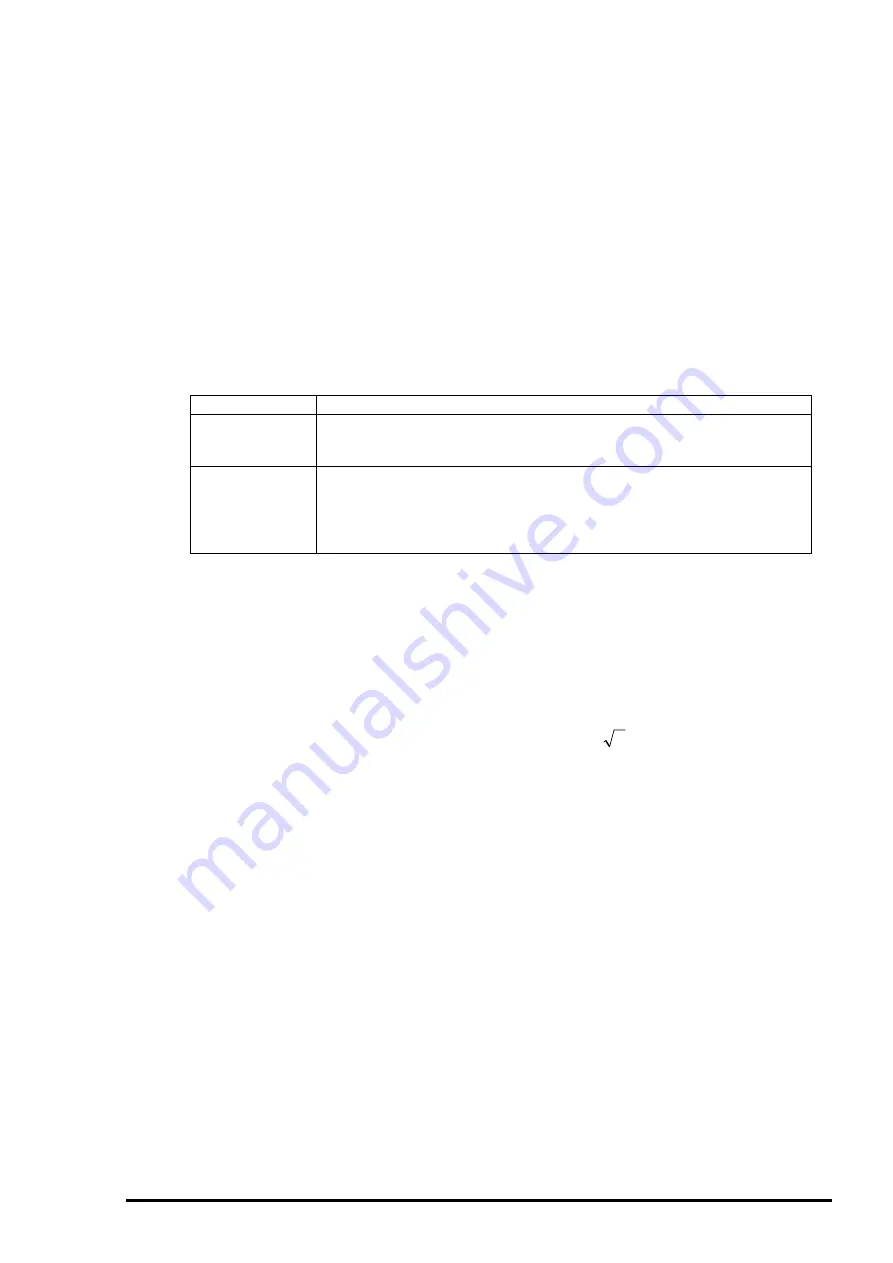

Table 2-12. Application of DC Voltage

Voltages

Application

+42VDC

CR Motor

PF/Pump Motor

Head driving power supply

+5VDC

Power supply for logic control

System control signal

Sensor circuit power supply voltage

LED panel drive power supply

Nozzle selector control signal power supply voltage

Figure 2-18 shows block diagram of C206 PSB/PSE board. The process from the input of AC100V to the

output of 42 V DC and 5 V is explained below.

1) Regardless of the state of power switch(On or OFF), the voltage is always applied in the primary

side of the power supply board from the moment or at the state that AC-plug is plugged in.

At this time, F1 plays a role of preventing AC100V from coming into the F1.

L1 and R1-R2 also prevent high harmonic wave noise generated in the RC circuit filter which consist

of C1

∼

C4 and R1

∼

R2 from going out, and eliminate the noise from outside here.

2) The AC is full-wave rectified by diode bridge DB1, and converted to

2

x AC in voltage by smoothing

electrolytic capacitor C11.

3) The pressured up direct current makes Q1 On through the starting resistor R31 and starts the primary

side of the circuit.

4) When the primary side is On state, the energy(current) led by the electromagnetic induction through

the trans (T1) does not flow to the secondary side since the diode(D51) on the secondary side

is installed in the opposite direction.

5) When the energy which is charged in the trans is reaching the saturated state, the voltage which

makes the Q1 On becomes weak gradually. At the point that this voltage drops at the

certain voltage, C13 absorbs the current in the opposite direction and Q1 is quickly shut off by

the resulting sharp drop.

6) When the primary side is turned off, the energy charged in the T1 is opened according to the

diode(D51) direction which is installed on the secondary side. Basically, 42 V DC is output

by these circuit operations and the number of T1 spiral coil .

7) +5VDC is generated by pressured down this +42VDC as power supply. IC51 pressures down the

+42VDC and generates p5VDC by chopping off the output, forming the standard santooth

wave form by the outer RC integration circuit.

Summary of Contents for Stylus Color 400

Page 5: ...REVISION SHEET Revision Issued Data Contents Rev A February18 1997 First issue ...

Page 126: ...Chapter 6 Maintenance Rev A 6 5 No 1 No 2 10mm 2mm 2mm No 3 No 11 GEAR 34 ...

Page 138: ...EPSON Stylus Color400 Service Manual Rev A A 9 Figure A 3 C206 PSB Board Component Layout ...

Page 139: ...Appendix Rev A A 10 Figure A 4 C206 PSE Board Component Layout ...

Page 140: ...EPSON Stylus Color400 Service Manual Rev A A 11 Figure A 5 C206 PNL Component Layout ...

Page 141: ...Appendix Rev A A 12 A 5 Exploded Diagrams Figure A 6 Stylus Color 400 Exploded Diagram 1 ...

Page 143: ...Appendix Rev A A 14 Figure A 8 Stylus Color 400 Exploded Diagram 3 ...

Page 145: ...EPSON SEIKO EPSON CORPORATION ...