Chapter3 Disassembly and Assembly

Rev. A

3-3

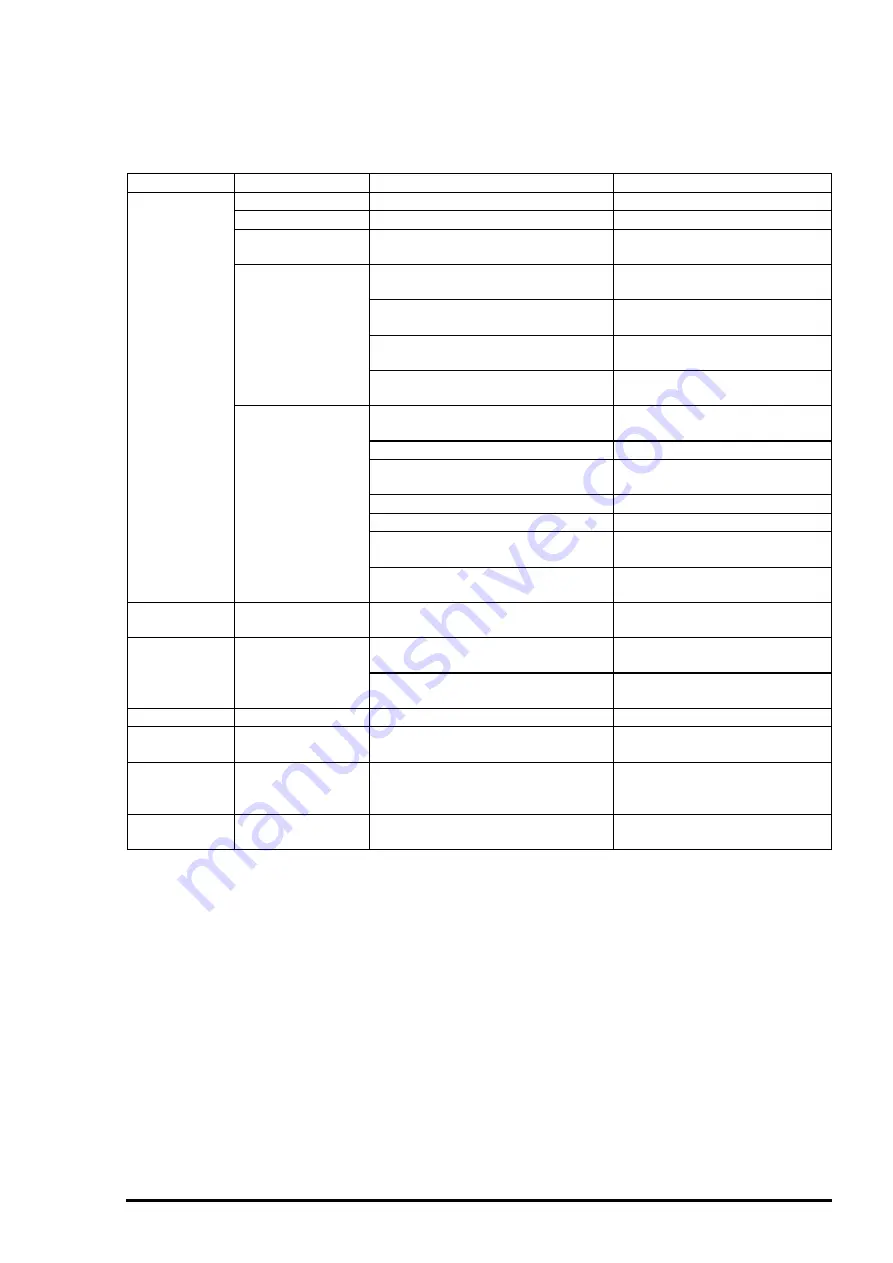

3.1.4 Service Checks After Repair

Before returning the printer after service, use the check list in Table 3-3, which provides a record to

make servicing and shipping more efficient.

Category

Component

Item to check

Is Check required?

Self-test

Is the operation normal?

Checked /

Not necessary

On-line test

Was the on-line test successful?

Checked /

Not necessary

Print head

Is ink ejected normally from the all

nozzles?

Checked

/

Not necessary

Carriage

mechanism

Does the carriage move smoothly?

Checked /

Not necessary

Any abnormal noise during

movement?

Checked /

Not necessary

Any dirt or obstacles around the

axis of carriage guide?

Checked

/

Not necessary

Printer units

Is the CR motor at the correct

temperature(not over heating)?

Checked

/

Not necessary

Paper feeding

mechanism

Is paper fed smoothly?

Checked

/

Not necessary

Does the paper get jammed?

Checked

/

Not necessary

Does the paper get skew during

paper feeding?

Checked

/

Not necessary

Are papers multi fed?

Checked

/

Not necessary

Does the PF motor get overheated?

Checked /

Not necessary

Abnormal noise during paper

feeding?

Checked /

Not necessary

Is the paper path clear of all

obstructions?

Checked /

Not necessary

Adjustment

Pointed adjustment

items

Are adjusted conditions all right?

Checked /

Not necessary

Lubricant

Pointed lubricant

item

Is lubrication applied to the pointed

locations?

Checked /

Not necessary

Is the quantity of lubrication

adequate?

Checked

/

Not necessary

Function

ROM version

Newest version:

Checked /

Not necessary

Shipment

package

Ink cartridge

Is the ink cartridge installed

correctly?

Checked /

Not necessary

Protection

conditions during

transport

Is all the pointed parts firmly fixed?

Checked /

Not necessary

Others

Attached items

Is all attached items from users

included?

Checked /

Not necessary

Table 3-3. Inspection Check List for the Repaired Printer

Summary of Contents for Stylus Color 400

Page 5: ...REVISION SHEET Revision Issued Data Contents Rev A February18 1997 First issue ...

Page 126: ...Chapter 6 Maintenance Rev A 6 5 No 1 No 2 10mm 2mm 2mm No 3 No 11 GEAR 34 ...

Page 138: ...EPSON Stylus Color400 Service Manual Rev A A 9 Figure A 3 C206 PSB Board Component Layout ...

Page 139: ...Appendix Rev A A 10 Figure A 4 C206 PSE Board Component Layout ...

Page 140: ...EPSON Stylus Color400 Service Manual Rev A A 11 Figure A 5 C206 PNL Component Layout ...

Page 141: ...Appendix Rev A A 12 A 5 Exploded Diagrams Figure A 6 Stylus Color 400 Exploded Diagram 1 ...

Page 143: ...Appendix Rev A A 14 Figure A 8 Stylus Color 400 Exploded Diagram 3 ...

Page 145: ...EPSON SEIKO EPSON CORPORATION ...