Stylus Photo 720

Revision B

Troubleshooting

Troubleshooting at Unit Level

22

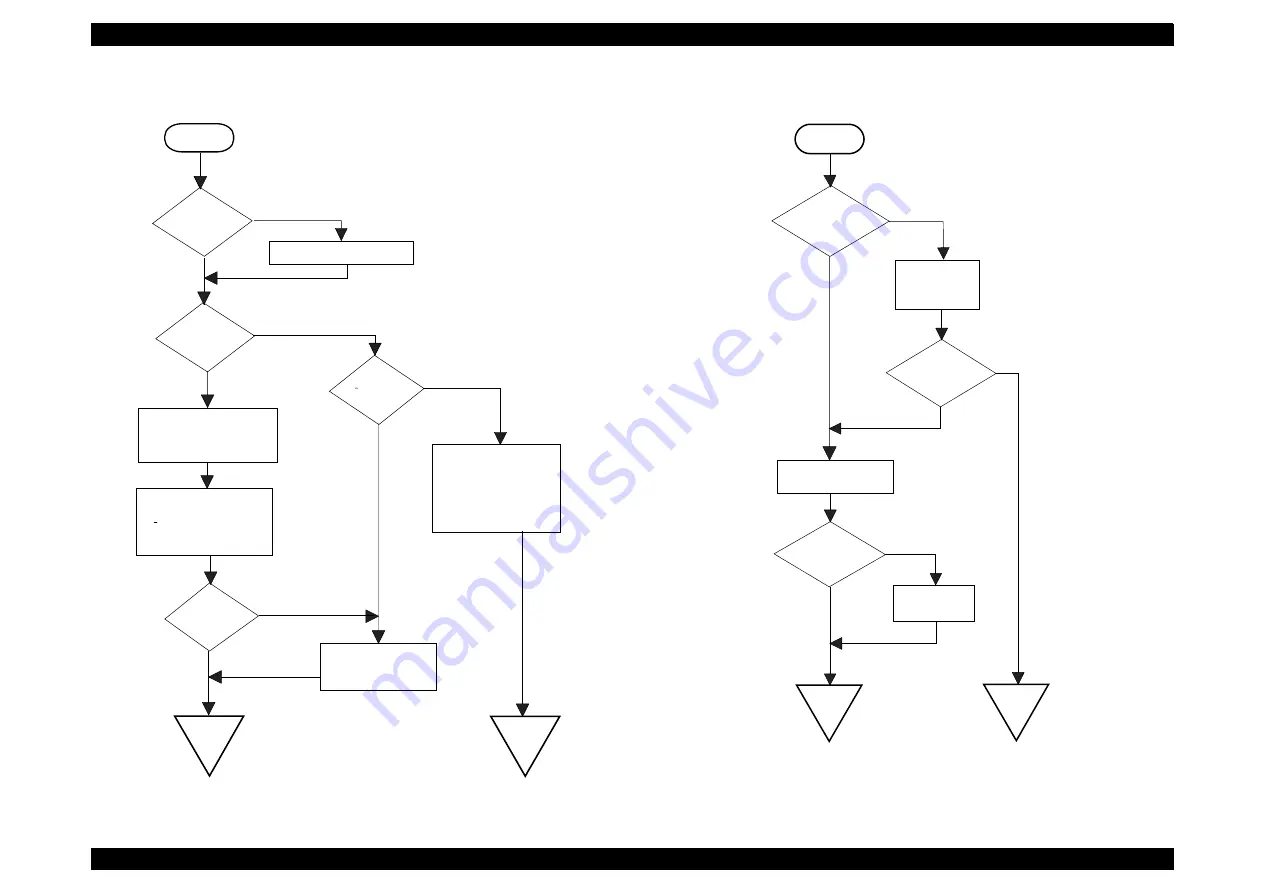

3.1.4 Paper feeding is not normally carried out

Flowchart 3-4.

3.1.5 Operation Panel faulty

Flowchart 3-5.

Start

Paper is

correctly set in

ASF?

Set paper correctly.

Paper loading

roller and PF roller

are correctly

rotating?

PF motor is

driving?

No

No

No

Yes

Check whether connector

of PF motor is connected

to CN7 of main board. If

it is connected properly,

replace main board.

Yes

Remove foreign matters,

if any, from paper route.

Clean rollers on paper

route. (Refer to

Problem is

solved?

Refer to

Yes

No

End

End

Yes

Operation

Panel is connected

properly with

cable?

Start

No

No

No

Yes

Yes

Yes

End

Problem is

solved?

Replace operation

panel.

Problem is

solved?

Connect correctly

Operation panel

again.

Replace main

board.

End

Summary of Contents for Stylus CX3100

Page 1: ...EPSON StylusCX3100 3200 Scanner Printer Copier SERVICE MANUAL SEOT02002 ...

Page 5: ...Revision Status Revision Issued Date Description A Augusut 1 2002 First Release ...

Page 8: ...C H A P T E R 1 PRODUCTDESCRIPTION ...

Page 13: ...C H A P T E R 2 OPERATINGPRINCIPLES ...

Page 17: ...C H A P T E R 3 TROUBLESHOOTING ...

Page 34: ...C H A P T E R 4 DISASSEMBLYANDASSEMBLY ...

Page 57: ...C H A P T E R 5 ADJUSTMENT ...

Page 74: ...C H A P T E R 6 MAINTENANCE ...

Page 80: ...C H A P T E R 7 APPENDIX ...

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ...EPSON Stylus CX3100 3200 Revision A Appendix Exploded Diagrams 88 7 4 Exploded Diagrams ...

Page 90: ...EPSON Stylus CX3100 3200 Revision A Appendix ASP List 89 7 5 ASP List ...