EPSON Stylus Pro 4400/4450/4800/4880/4880C

Revision C

Product Description

Operating Panel

75

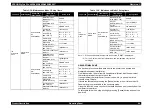

Print quality setup values set by MW print adjustment.

Table 1-34. MW print adjustmen List

Mode

ESC(i

Raster

resolution

Dot size

bit/pixel

OL

resolution

DS

range

remarks

Panel setting

UNIT

No

Mode ID

Restriced

functions

n1

n2

ESC(D

ESC ( e

Colors

Horizontal

resolution

Vertical

resolution

No

8colors

00h

-

360x180

VSD1/VSD2/

VSD3_N

2

DMW

360x180

-

Standard/1/2

10

8

360

180

0

00h

-

720x180

VSD3_HR

1

DMW

720x180

-

Standard/1/2

20

8

720

180

0

01h

10h

360x360

VSD1(ECO)

1

M/F

360x360

-

This setting is

recommended for

360 x 360 M/F

setting.

Standard/1/2

30

8

360

360

1

00h

00h

360x360

VSD1(ECO)

1

M/F

360x360

-

Provided for

supporting drivers

of conventional

models.

Standard/1/2

30

8

360

360

1

01h

00h

360x360

VSD1

2

FD+36POL

360x360

-

Standard/1/2

40

8

360

360

0

01h

00h

360x720

VSD1

2

FD+21POL

360x720

-

Standard/1/2

50

8

360

720

0

01h

00h

720x360

VSD1

2

FOL+36POL

720x360

-

Standard/1/2

60

8

720

360

0

01h

00h

720x360

VSD2

2

FOL+36POL

720x360

-

Standard/1/2

70

8

720

360

0

01h

10h

720x720

VSD2

2

FOL+21POL

720x720

-

1

80

8

720

720

0

01h

00h

720x720

VSD2

2

FOL+48POL

720x720

0

±

3

Standard

81

8

720

720

1

01h

20h

720x720

VSD2

2

FOL+46POL

720x720

0

±

5

2

82

8

720

720

2

01h

00h

1440x720

VSD3_N

2

FOL+11POL

1440x720

-

Standard

90

8

1440

720

0

01h

10h

1440x720

VSD3_N

2

FOL+28POL

1440x720

-

1

91

8

1440

720

1

01h

20h

1440x720

VSD3_N

2

FOL+11POL

1440x720

-

2

92

8

1440

720

2

01h

30h

1440x720

VSD3_N

2

FOL+90POL

1440x720

-

Equivalent to 8pass

-

93

8

1440

720

3

01h

00h

2880x1440

VSD3_HR

1

FOL+6POL

2880x1440

-

Standard/1/2

A0

8

2880

1440

0

01h

00h

1440x1440

VSD3_N

2

FOL+6POL

1440x1440

-

The standard driver

does not support

this setting.

Standard/1/2

B0

8

1440

1440

0

Borderless is

not available

01h

00h

2880x2880

VSD3_HR

1

FOL

2880x2880

-

The standard driver

does not support

this setting.

Standard/1/2

C0

8

2880

2880

0

Borderless is

not available

Top & bottom

margins are

extended

01h

10h

2880x2880

VSD3_HR

1

FOL

2880x2880

-

The standard driver

does not support

this setting.

For monochrome

only

Standard/1/2

C1

8

2880

2880

1

Borderless is

not available

Top & bottom

margins are

extended

Summary of Contents for Stylus Pro 4800 Portrait Edition

Page 9: ...C H A P T E R 1 PRODUCTDESCRIPTION ...

Page 113: ...C H A P T E R 2 OPERATINGPRINCIPLES ...

Page 156: ...C H A P T E R 3 TROUBLESHOOTING ...

Page 200: ...C H A P T E R 4 DISASSEMBLY ASSEMBLY ...

Page 366: ...C H A P T E R 5 ADJUSTMENT ...

Page 448: ...C H A P T E R 6 MAINTENANCE ...

Page 457: ...C H A P T E R 7 APPENDIX ...