Rev.C

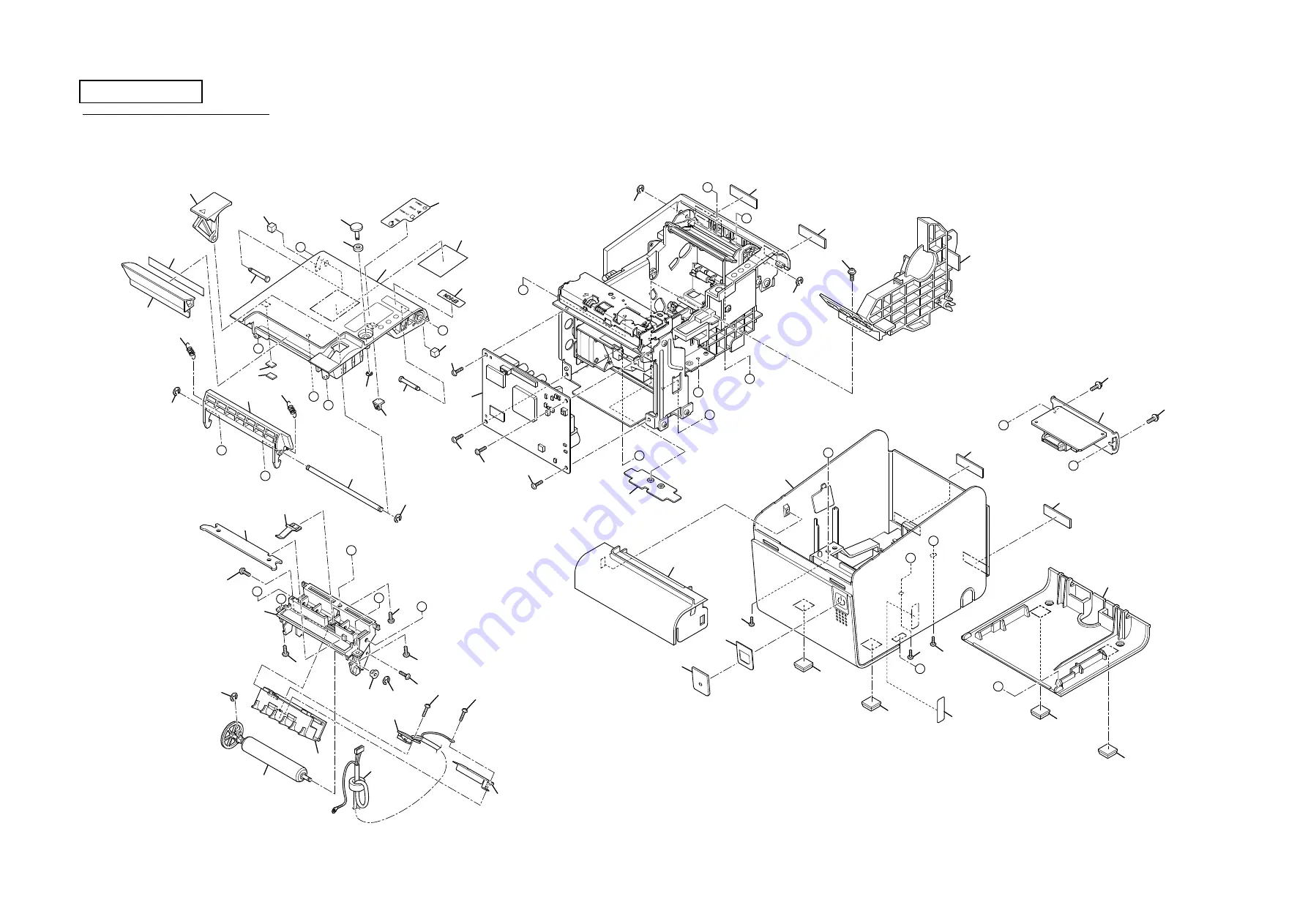

Parts List Appendix D-11

TM-L90 Service Manual

Confidential

Overall Exploded Diagram

Case Unit

131

130

133

171

152

155

158

123

129

179

123

128

104

114

156

163

112

164

180

213

102

157

160

139

201

136

173

141

202

140

106

140

159

132

E2

E2

S6

E2

E2

E2

S1

S5

S3

S6

S6

S5

S7

S1

E2

211

E2

S1

140

140

S6

172

172

175

174

S6

S6

S7

S7

S7

159

159

159

S10

133

178

E

H

G

A

C

B

L

N

C

K

A

B

J

H

I

G

K

F

F

N

E

D

D

I

J

L