Appendix B-4

Overview of the Mechanisms

Rev.B

Confidential

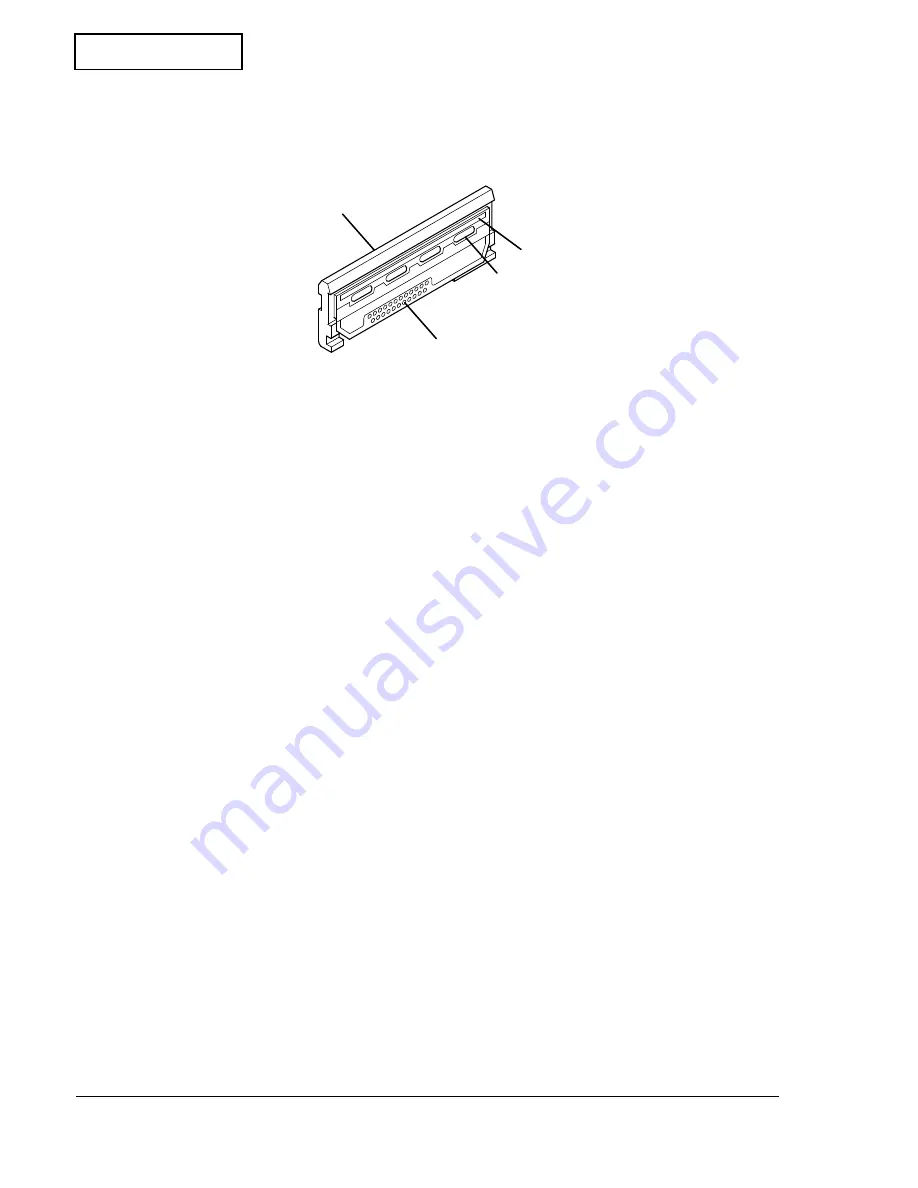

Thermal Print Head

The thermal print head consists of a head chip that includes the heating element, a driver IC that

controls each dot of the heating element, a thermistor that detects the temperature of the thermal

print head, radiation plate, and connector.

Principles of Thermal Printing

When the print signal energizes a corresponding dot of the heating element with the specified

pulse, the dot heats up to a high temperature, and dissolves the color-forming ingredient of the

color-forming layer on the thermal paper that is contacting the dot. When the transparent color-

forming layer is dissolved at room temperature, it generates color. When the temperature cools

down, it is fixed again to the thermal paper side, thus forming printing.

The color can be set to various colors by changing the formulation of chemicals used for the

color-forming layer, but the popular thermal paper is the one that forms the color black.

Depending on the paper type, environment, and printing conditions, part of the dissolved color-

forming layer may be deposited on the thermal printer head side. In this case, you need to clean

the heat-generating element of the thermal print head.

Data Input and Printing

Serial print data input from DATA IN synchronizes with the CLOCK signal, and is transmitted

to the SHIFT REGISTER within the driver IC. It is then recorded to the LATCH REGISTER

within the driver IC on the LATCH signal timing, turns on the gate with the STROBE signal, and

energizes the heating element.

The STROBE signal (energizing pulse width) is set properly, depending on the voltage,

thermistor-detected temperature, and print speed, to obtain the optimum print density. There

are two terminals for STROBE, which can be driven with up to two parts by hardware. Normal

printing performs one-part printing for printing speed, and two-part printing for high-duty

printing, which causes a high-voltage drop.

Radiation plate

Head chip

Driver IC

Connector