36

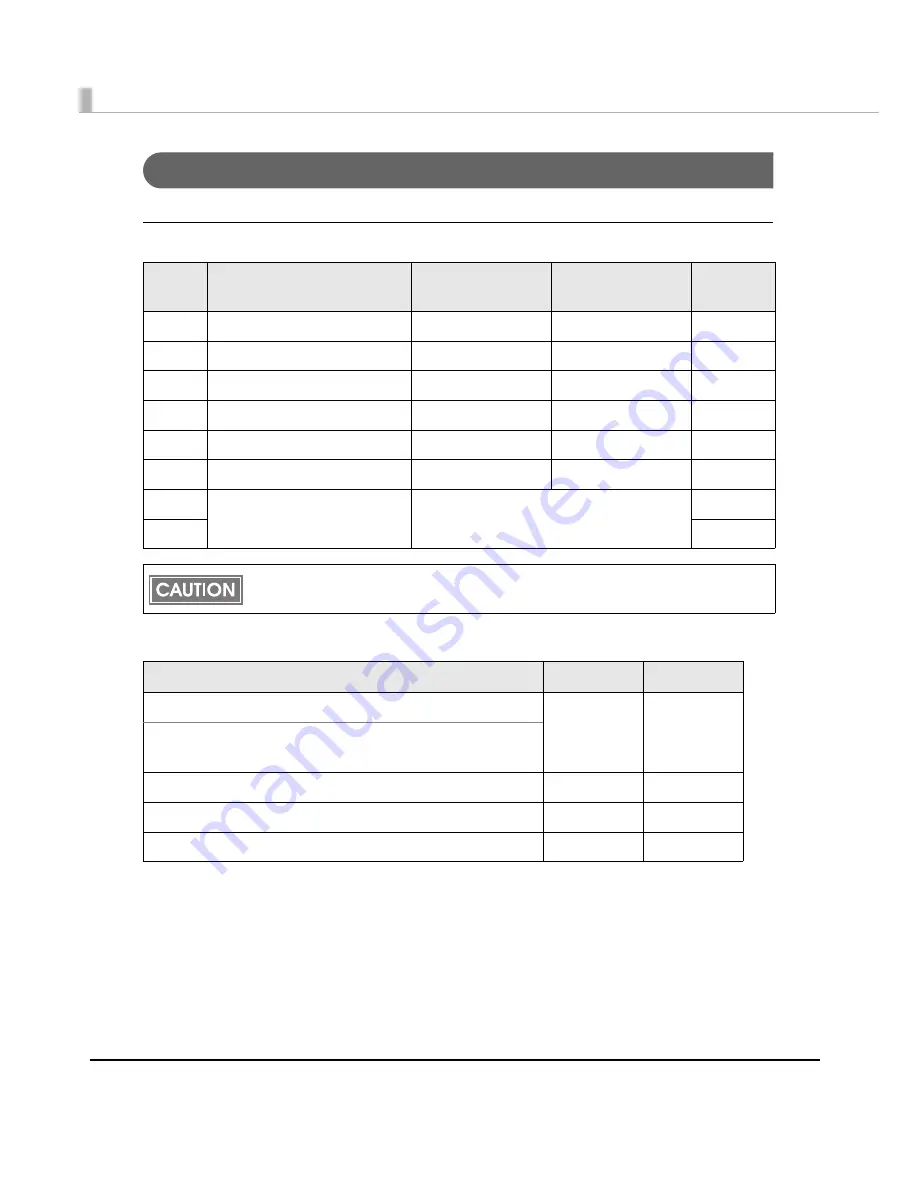

For Serial Interface

DIP Switch Bank 1

Transmission speed (DIP switch 1-7/1-8)

bps: b

it

s per seco

n

d

SW

Function

ON

OFF

Factory

setting

1-1

Data reception error

Ignored

Prints “?”

OFF

1-2

Receive buffer capacity

45 bytes

4 KB

OFF

1-3

Handshaking

XON/XOFF

DTR/DSR

OFF

1-4

Word length

7 bits

8 bits

OFF

1-5

Parity check

Yes

No

OFF

1-6

Parity selection

Even

Odd

OFF

1-7

Transmission speed selections

See the

“ Transmission speed (DIP switch 1-

7/1-8)”

table below.

ON

1-8

OFF

For DIP switch 1-2 (Receive buffer capacity), see also DIP switch 2-5 (Setting the release

condition of the receive buffer BUSY state).

Transmission speed (bps)

SW 1-7

SW 1-8

38400 (Initial value)

ON

ON

2400, 4800, 9600, 19200, 38400, 57600, 115200

(When setting with a command/Memory Switch Setting Utility)

4800

OFF

ON

9600

ON

OFF

19200

OFF

OFF