OPERATOR INSTRUCTION MANUAL

IM_NS12_15_20TI_Rev03_A4

NS12TI, NS15TI, NS20TI

INTEGRAL HYDRAULIC NUT SPLITTER

5

If the specification of the nut is unknown then a vernier

calliper or measure tape should be used to determine

the Across-Flats (A/F) size of the nut to be split and the

correct tool.

A/F

3.

TOOL OPERATION

3.1

GENERAL GUIDANCE

The Equalizer™ Nut Splitter Tools have been designed to

fit a range of nut sizes and grades and the correct tool

should be selected prior to commencing work by following

the instructions in this section.

CAUTION: A thick grease should be applied to

the Cutting Tip before every cut. This will

ease the splitting operation, prolong the life of

the Cutting Tip and limit the risk of sparking

and debris projectiles.

3.2

TOOL SELECTION

CAUTION: It is important that the correct tool

is selected for each nut and the correct Cutting

Tip is used for each tool. Each tool in the Nut

Splitter range comes with the appropriate

Cutting Tips for that tool. Please refer to the

table below to choose the correct tool for your

application.

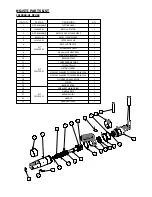

NS TOOLS

UNC HEAVY HEX

STUD SIZE

UNC HEAVY

NUT A/F SIZE

METRIC

STUD SIZE

METRIC

NUT A/F SIZE

NS12

1/2”, 5/8”

0.88” to 1.06”

M12, M16, M20

19 mm to 30 mm

NS15

3/4”, 7/8”

1.25” to 1.44”

M16, M20, M22

24 mm to 32 mm

NS20

7/8”, 1”, 1-1/8”

1.44” to 1.81”

M24, M27, M30

36 mm to 46 mm

NS36

1-1/4”, 1-3/8”,

1-1/2”, 1-5/8”

2” to 2.56”

M33, M36, M39, M42

50 mm to 65 mm

NS50

1-5/8”, 1-3/4”,

1-7/8”

2.56” to 2.94”

M42, M45, M48

65 mm to 75 mm