OPERATOR INSTRUCTION MANUAL

IM_NS12_15_20TI_Rev03_A4

NS12TI, NS15TI, NS20TI

INTEGRAL HYDRAULIC NUT SPLITTER

9

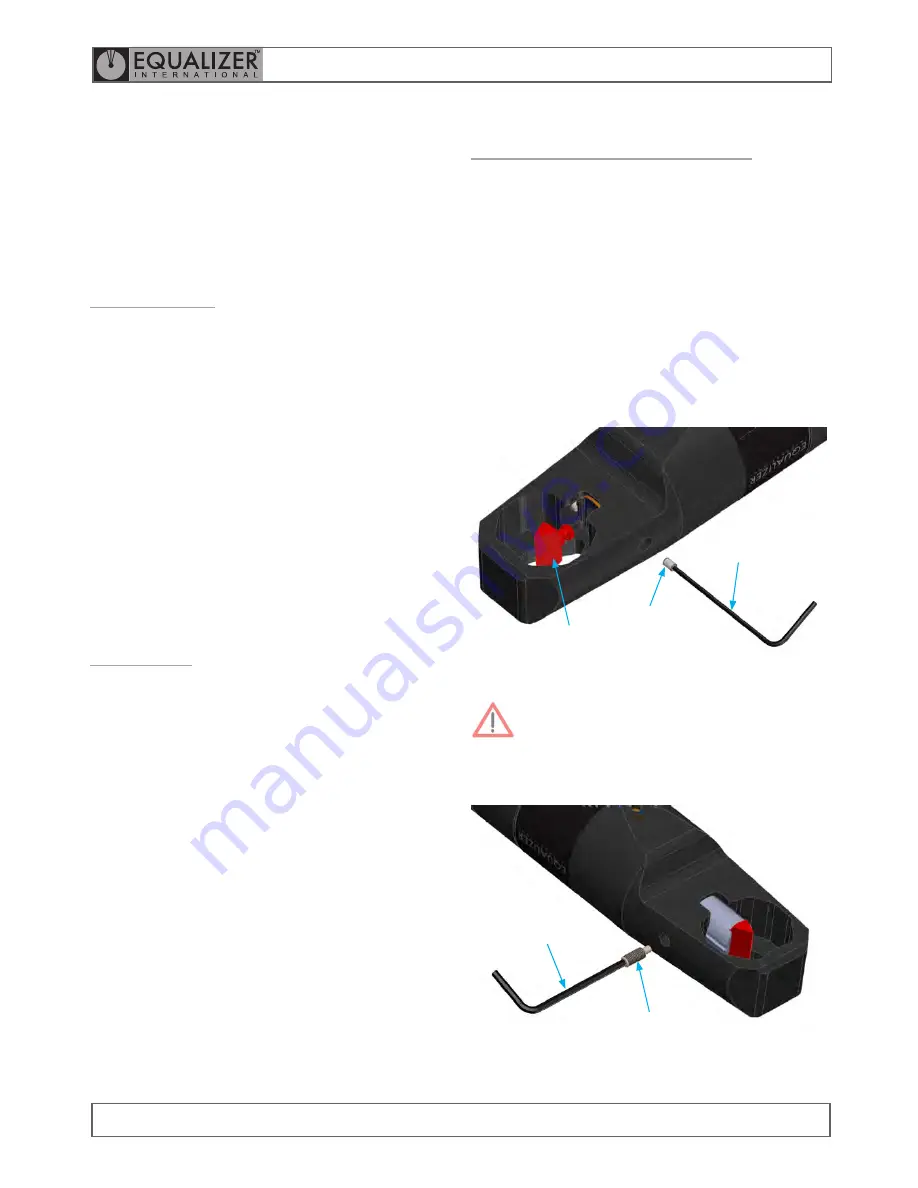

4.3

CUTTING TIP REPLACEMENT

Ensure the correct Cutting Tip is fitted to the tool and

has been checked for damage. Some minor bluntening is

acceptable, but cracked or chipped Cutting Tips should be

replaced.

The Cutting Tip is retained in the piston by the tip retention

screw. Unscrew the tip retention screw with a hex-key and

pull the Cutting Tip out to replace. Do not apply excessive

force when inserting the Cutting Tip into the tool. If the

Cutting Tip does not come out easily, slightly extend the

piston to gain better access. When replacing the Cutting

Tip, the tip retention screw and alignment screw should

also be replaced every time.

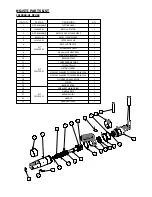

TIP RETENTION SCREW

SMALLER HEX KEY

CUTTING TIP

CAUTION: Ensure the retention grub screw is

fully inserted in the piston before actuating the

tool.

ALIGNMENT SCREW

LARGER HEX KEY

4.

TOOL MAINTENANCE

4.1

INSPECTION

A thorough inspection should be carried out prior to usage,

storage or transportation to ensure the completeness and

condition of the tool.

Inspection should include:

•

visual inspection of the outer parts of the tool,

checking for obvious damage, degradation or missing

parts

•

visual inspection of the Cutting-Tip (this may require

tool actuation)

Cleaning and servicing should be undertaken as required

prior to the tool being used, stored or transported.

4.2

CLEANING

To lightly clean the tool, wipe gently with a damp cloth.

If more thorough cleaning is required (for example

following immersion in water) carry out the following

cleaning procedure:

•

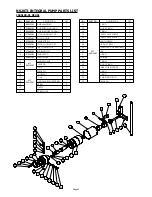

strip the tool down, observing the schematics in

section 8

•

clean the components using detergent, following the

manufacturer’s guidelines

•

rinse the components to remove traces of detergent

•

dry the components thoroughly

Inspect, service and lubricate the tool immediately after

the cleaning process.