OPERATOR INSTRUCTION MANUAL

IM_TFA_12TE_Rev03_A4

TFA12TE

FLANGE ALIGNMENT TOOL

4

WARNING: Applying pressure to a damaged

hose may cause it to rupture.

WARNING: Immediately replace worn or

damaged parts. Use only genuine Equalizer

parts from approved distributors or service

centres. Equalizer parts have been engineered

and manufactured to be fit-for-purpose.

DANGER: To minimise risk of personal injury

keep hands and feet away from the tool and

workpiece during operation.

WARNING: Always wear suitable clothing and

Personal Protective Equipment (PPE). Do not

handle pressurised hoses; escaping oil under

pressure can penetrate the skin, causing serious

injury. Seek medical attention immediately if oil

penetration is suspected.

WARNING: Only pressurize complete and fully

connected hydraulic systems. Do not pressurize

systems that contain unconnected couplers.

CAUTION: Do not lift hydraulic equipment by

the hoses or couplers. Use only the designated

carrying handles.

CAUTION: Lubricate tools as directed in this

manual prior to operation. Use only approved

lubricants of high quality, following the lubricant

manufacturers instructions.

The vibration total value to which this tool is

subjected does not exceed 2.5 m/s

2

.

2.4

DEFINITION OF TERMS

A CAUTION is used to indicate correct operating or

maintenance procedures and practices to prevent damage

to, or destruction of equipment or other property.

A WARNING indicates a potential danger that requires

correct procedures or practices to avoid personal injury.

A DANGER is only used when your action or lack of action

may cause serious injury or even death.

DO: an illustration showing how the tool should

be used.

DON’T: an illustration showing an incorrect

way to use a tool.

2.5

HAZARDS

WARNING: ensure all hydraulic components

are rated to a safe working pressure of 700 bar

(10 000 psi).

WARNING: Do not overload equipment. The

risk of hydraulic overloading can be minimised

by using the Equalizer Hand Pump, which has a

factory-set safety valve preventing the safe

working pressure being exceeded.

If alternative hydraulic pumps are used, ensure

that there are adequate systems to limit the

working pressure to 510 bar (7400 psi).

CAUTION: ensure components are protected

from external sources of damage, such as

excessive heat, flame, moving machine parts,

sharp edges and corrosive chemicals.

CAUTION: Take care to avoid sharp bends and

kinks in hydraulic hoses. Bends and kinks can

cause severe back-up pressure and cause hose

failure. Protect hoses from dropped objects; a

sharp impact may cause internal damage to

hose wire strands. Protect hoses from crush

risks, such as heavy objects or vehicles; crush

damage can cause hose failure.

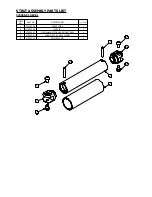

Summary of Contents for TFA12TE

Page 27: ......