14

Lubricate the Axle Engagement System

In the drive system is a grease fitting. This fitting should be lubricated every 40 hours to ensure proper

operation. To access the grease fitting:

1. Engage Parking Brake.

2. Lower the outriggers.

3. Release the safety latch and raise the

front steering wheels completely.

4. Tilt the dump box to gain access to the

top of the drive axle. Place the support arm

under the dump box before entering the area

under the dump box.

NOTE: If the grease fitting is rotated away

and cannot be accessed, the drive system

can be operated to spin the drive shaft.

Use the drive control lever to “bump”

the system until the grease fitting is

accessible.

5. Apply lubricant as needed.

Engine Operation

This manual is intended to provide an overview of how the engine works within the Equipter. Additional

information regarding engine operation and maintenance is available within the Engine Manual supplied

with the machine.

The engine is used to drive a hydraulic pump. The hydraulic pump then powers various cylinders and

the drive motor. Engine controls consist of a keyed ignition switch, choke, remote ignition switch, remote

throttle, and fuel shut-off valve. The ignition switch has three positions: OFF, ON, and START.

The engine has a rope pull-start in the event the battery is not operational (ignition switch must be in the

ON position to pull-start).

RB4000s produced in 2018 and later feature a remote ignition switch on the operator’s station,

underneath the remote throttle. This allows the operator to easily engage the engine from the control

panel rather than through the engine cage.

The remote ignition switch will only engage if the engine key is in the On position. If the key is switched

to Off, the engine will crank but will not fire.

The throttle is located at the operator station next to the directional control lever. Press red button in

center of knob to adjust throttle, release button to lock. More gradual adjustment of throttle can be made

by turning black knob. When starting a cold engine, pull throttle part way out, slide choke lever toward

the front of the Equipter. After the engine is running, slowly move the choke into the run position. If the

engine is warm, choke operation should not be necessary.

The engine should be turned OFF after the machine is positioned for loading.

Place the support arm under the dump box

to provide extra safety while lubricating the

axle engagement system.

Summary of Contents for RB4000

Page 2: ......

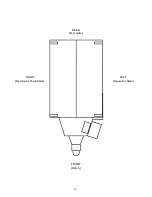

Page 6: ...iv RIGHT Hydraulic Tank Side REAR Tail Gate LEFT Operator Side FRONT Hitch ...

Page 9: ...3 Figure 2 Decals ...

Page 45: ......

Page 46: ...855 378 4783 www equipter com 49 Eagle Drive Leola PA 17540 ...