4. Remove the chisel

Pull back fastening sleeve, hold and remove tool.

(See Fig 2)

Note:

The chisel tools are gripped firmly by the

shank and can not be removed once locked in

position.

If the chisel tool is not located repeat the

installation operation again.

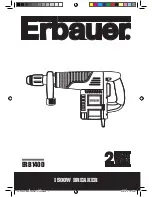

5. Operating the On / Off switch

To operate the tool, push the switch right to turn

on and to left to stop. (See Fig 3)

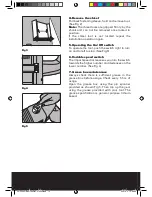

6. Variable speed switch

The impact speed increases as you turn the switch

towards the higher number and decreases on the

lower number. (See Fig 4)

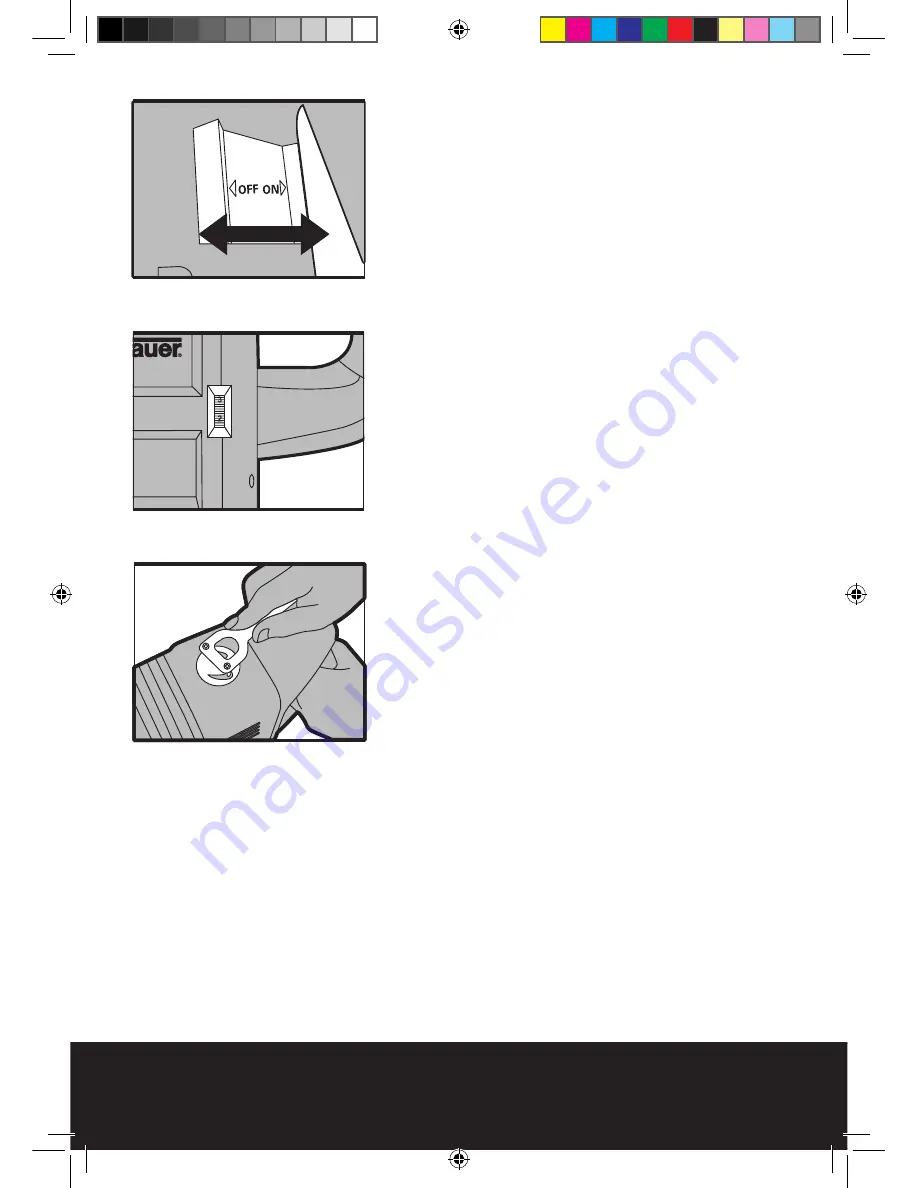

7. Grease box maintenance

Always check there is sufficient grease in the

grease box before usage. Check every 5 hrs of

usage.

Open the grease box using the pin spanner

provided as shown Fig 5. Then top up the gear

using the grease provided with your tool. The

grease specification is general purpose lithium

based.

Fig 5

Fig 4

Fig 3

PDH140D EBR140D-M-070303.indd 10

2007-3-2 15:39:03

Summary of Contents for ERB140D

Page 1: ...1500W BREAKER WARRANTY YEARS ERB140D PDH140D EBR140D M 070303 indd 1 2007 3 2 15 39 01...

Page 2: ...PDH140D EBR140D M 070303 indd 2 2007 3 2 15 39 01...

Page 15: ...1500W BREAKER PDH140D EBR140D M 070303 indd 15 2007 3 2 15 39 04...

Page 16: ...PDH140D EBR140D M 070303 indd 16 2007 3 2 15 39 04...