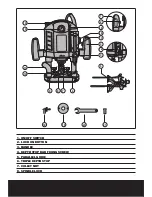

ROUTER

0

1

2

3

4

5

6

7

1

2

11

12

13

Loos

en

Tighten

0

1

2

3

4

5

6

7

1

2

11

12

13

Tighten

Loos

en

router back to its original position. The depth of

cut is now set, see “Starting the router” section

for final operation.

Before proceeding carry out test cut on waste

timber.

Method 2: Using the scale method

Fit the router bit, loosen the depth stop bar fixing

screw and release the plunge lock lever.

Lower the router down until it contacts the

workpiece, lock into this position with the plunge

lock lever. The scale on the depth bar now shows

the starting position. Note the starting position

will vary depending on the bit used.

Next add the required depth of the cut to the

starting position, i.e.: if the scale shows 20mm

and you require a cut of 10mm, then the correct

adjustment on the scale is 20+10=30mm, if the

scale shows 38mm and the required cut is 6mm

in depth, the adjustment on the scale will be

38+6=44mm.

Now move the depth stop bar to the calculated

number, and lock bar with the fixing screw.

Release the clamp lock lever, the router will return

to its original position.

Start Router as described in “Starting the router”

section below.

Before proceeding carry out test cut on waste

timber.

4. MAKING FINE ADJUSTMENT TO CUT

DEPTH

To make fine adjustments, turn the triple depth

stop by loosening the centre screw, lift the stop

and turn to a suitable length screw, release stop

and tighten centre screw.(Fig9)

Turn the appropriate screw with a screwdriver to

obtain fine adjustment (Fig10).

Note all three screws can be adjusted, enabling

you to make different depth cuts on the same

workpiece.

If you wish to make a deep cut it is best to do this

in 2 or 3 stages. Do not cut more than 10mm depth

at a time i.e. If cutting 30mm make 3 separate

10mm cuts. The triple depth stop, can be used for

this purpose by making small variations in the 3

positions available.

If you want to make some accurate adjustment,

micro- adjustment can be made by turning the

micro depth adjustment knob (Fig11). A full turn

is equal to 1mm.

Fig 6

Fig 8

Fig 9

Loosen

Tighten

Fig 7

Summary of Contents for ERB210C

Page 1: ...ROUTER ERB210C WARRANTY YEARS ...

Page 2: ......

Page 18: ......

Page 19: ...ROUTER ...

Page 20: ......