4. DUST EXTRACTION (See Fig.4)

1) Internal dust extraction with dust bag (13).

For small cutting jobs, the dust bag can be used.

Connect it with the dust extraction adapter and

Insert to the dust outlet (8).

Empty the dust bag regularly.

2) External dust extraction

Connect a suitable vacuum cleaner to the dust

outlet (8) through the dust extraction adapter (18)

.

STARTING OPERATION

Warning:

•

When working with the machine, always hold

it firmly with both hands and provide for a

secure stance.

The power tool is guided more

secure with both hands. Hold the routing motor

with one hand and the auxiliary handle with the

other hand.

• Keep your hands away from the cutting area

and the cutting disc.

• Apply the machine to the workpiece only

when switched on.

Otherwise there is danger

of kickback when the cutting tool jams in the

workpiece.

1. SWITCHING ON AND OFF

To switch on the machine, push the On/Off switch

forward and press it down at the front to lock on.

To switch off the machine, press down the On/Off

switch at the rear so that the switch springs back to

the off position.

2. MARKING THE WORKPIECES (See Fig.5)

Before starting operation, the workpieces must be

marked as following.

Place the two workpieces, which must be

connected, on top of each other. Fasten the

workpieces and mark the centre of the groove.

Smaller workpieces don’t have to be marked.

3. SELECTION OF THE BISCUIT DOWEL (See

Fig.6)

For a solid connection, use the largest possible

biscuit dowel. Appropriate biscuit dowels are

recommended to use according to Fig.6.

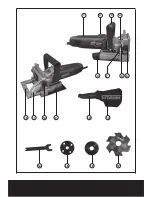

Fig. 1

Fig. 4

Fig. 3

A

Fig. 5

Fig. 8

Fig. 9

Fig. 7

Fig. 6

12

11

18

13

8

4

10

7

5

6

B

C

D

E

Fig. 2

Summary of Contents for ERB372BJC

Page 1: ...860W BISCUIT JOINTER ERB372BJC...

Page 2: ...Original Instructions Version 2 0...

Page 12: ...3 5 4 2 6 7 8 9 10 11 12 13 18 14 1 15 16 17...

Page 21: ......

Page 22: ......