860W BISCUIT JOINTER

4. CUTTING GROOVE JOINTS (See Fig.7)

The various adjustments on the adjustable height

/ angle stop will enable you to make virtually any

biscuit joint imaginable. The tool may be further

enhanced by some simple jigs and fixtures that can

be easily made. Some of the more common biscuit

joinery applications are shown in Fig.7.

Note:

E:

EDGE TO EDGE JOINT

F:

EDGE MITRE JOINT

G:

OFFSET

H:

OFFSET JOINT

I:

CORNER JOINT

J:

“T” JOINT

K:

45

0

FRAME JOINT

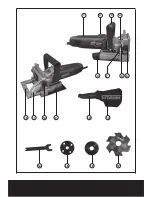

5. REPLACING THE CUTTING DISC (See Fig.8,

9)

Turn the machine around so that the base plate

faces upward.

Loosen the four screws (E) and remove the base

plate. Press the spindle lock button and keep it

pressed. Loosen and remove the outer flange with

the two-pin spanner. Take out the old cutting disc

and replace with a new one on the inner flange.

Important:

Make sure that the cutting direction of the teeth

(direction of the arrow on the disc) is visible and

corresponds with the direction of the arrow inside

of the base plate.

Position the outer flange back. With the spindle

lock button

(4)

pressed, tighten it with the spanner.

Note:

Make sure that the outer flange is placed in

correct side on the spindle.

Release the spindle lock and check if the

cutting disc is properly mounted and rotates

freely.

Place the base plate back and install the four

screws to tighten firmly.

Warning:

Make sure that the base plate is

locked securely before operation.

Fig. 1

Fig. 4

Fig. 3

A

Fig. 5

Fig. 8

Fig. 9

Fig. 7

Fig. 6

12

11

18

13

8

4

10

7

5

6

B

C

D

E

Fig. 2

Summary of Contents for ERB372BJC

Page 1: ...860W BISCUIT JOINTER ERB372BJC...

Page 2: ...Original Instructions Version 2 0...

Page 12: ...3 5 4 2 6 7 8 9 10 11 12 13 18 14 1 15 16 17...

Page 21: ......

Page 22: ......