Preventive Maintenance

Swiss Egro 50 Serie

Egro Coffee Systems AG

CH-5443 Niederrohrdorf

15.05.09

Page 3

1.

Preventive Maintenance

Preventive maintenance (PM) ensures a continuous good quality of coffee products and reduces the

unscheduled break downs of the coffee machine. During preventive maintenance recommended services

will be done and necessary spare parts will be exchanged. Moreover it simplifies the organisation of the

maintenance and the spare parts logistics.

The bases for preventing maintenance are our service kits, along with all necessary spare parts. These

are available as “PM Service kit” and “PM Extension kit”.

The preventive maintenance is controlled by the number of brewing cycles, counted in the coffee

machine. Reaching the number of cycles, the coffee machine is indicating following message in the

display "PM Service Req.".

Egro Coffee System AG recommends adjusting the maximum brewing cycles for preventive maintenance

to 15’000 cycles. For coffee machines with the brewing unit “NBUP” (New Brewing Unit Project) the

number of cycles will be with 25’000.

The brewing cycles depend on various criteria as regularity of brewing, composition of water, cleaning

product, climatic conditions, etc. Egro Coffee System AG recommend, in case of unfavorable conditions,

to adjust the number of brewing cycles.

2.

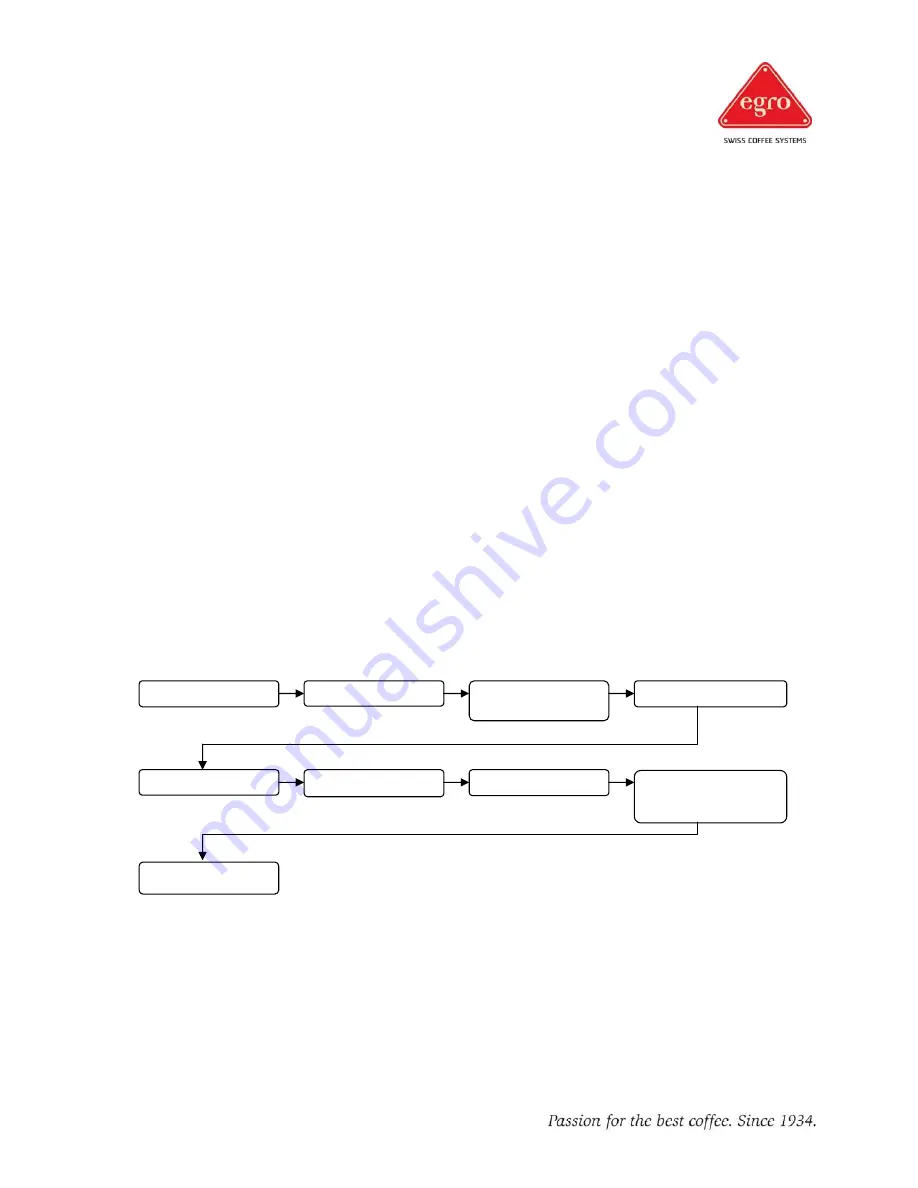

Programming manual

Put the machine in programming mode (mode 4).

Readout the brewing cycles: The parameter "P-Serv" informs how many brewing cycles the coffee

machine has done, since the last maintenance.

Choose menu „Service“

Enter Pin 1849

Display shows

„Product Total..“

Pin ....

Press Enter

Choose „P-Serv“

Disp. „P-Serv 12’789“

12’789 corresponds to

the cycles

since the last

maintenance

Turn key back