Crack-Vac Model 100G Manual

Chapter 6 Maintenance Instructions

©2020 by Crafco, Inc. All Rights Reserved

Maintenance Instructions 6-10

Step

Action

1

Turn the system on and allow it to reach full pressure.

2

Slow engine speed to idle and turn the ignition key to “OFF”

3

Listen for the pressurized air to blowdown through the muffler on the WHASP tank.

Blowdown should be completed in approximately 20 seconds.

4

If the muffler is showing signs of blockage, replace the muffler.

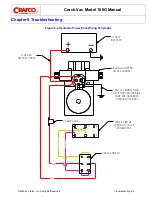

Pressure Relief Valve

Step

Action

1

Visually inspect the valve and ensure it is not corroded and that the vent holes are

not plugged.

2

Turn the system on and allow it to reach full system pressure.

3

Ensure that air does not leak out of the valve. Air leaking from the pressure relief

valve when system pressure is at or below 150 psi indicates that the spring in the

valve is worn and the valve must be replaced.

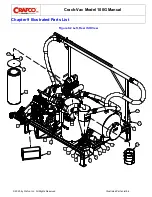

Coalescing Filter

Step

Action

1

Clean the WHASP tank around the coalescing filter to prevent contamination.

2

Remove the coalescing filter by turning it counterclockwise.

3

Clean the gasket sealing surface and inspect it for damage. The surface must be

free of old gasket material and smooth to ensure a good seal.

4

Apply a thin coat of compressor oil to the rubber gasket on the new coalescing

filter.

5

Spin the new filter onto the threaded nipple until the gasket contacts the sealing

surface on the tank, then tighten the filter an additional ¾ to 1 turn to seat the

gasket.

6

Start the engine and check for oil leaks. Allow the system to build pressure and

shutdown the system. Relieve all pressure from the system.

Table 6-5 Testing the Blowdown Muffler

The pressure relief valve is a regular service item and must be replaced every 1000 hours of

operation. Inspect the pressure relief valve for signs of corrosion or loss of functionality. Reference

Table 6-6 Testing the Pressure Relief Valve

Table 6-6 Testing the Pressure Relief Valve

The coalescing filter is a regular service item and must be replaced every 1000 hours of operation.

Reference

Table 6-7 Replacing the Coalescing Filter

Table 6-7 Replacing the Coalescing Filter

Summary of Contents for 60800N

Page 1: ...CRACK VAC MODEL 100G Operator Parts Manual 26627N Revision O ...

Page 3: ...Crack Vac Model 100G Manual Revisions Revision Date ...

Page 4: ...CRACK VAC MODEL 100G with COMPRESSOR P N 60900N CRACK VAC MODEL 100G P N 60800N ...

Page 10: ......

Page 12: ......

Page 18: ......

Page 22: ......

Page 40: ......

Page 77: ......

Page 78: ... 2020 Crafco Inc ...