Crack-Vac Model 100G Manual

Chapter 6 Maintenance Instructions

©2020 by Crafco, Inc. All Rights Reserved

Maintenance Instructions 6-12

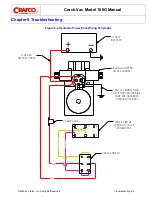

Compressor Drive Belt

Inspect both pulleys and the idler for damage. If any component shows signs of cracks, chipping,

impact damage or any other signs of damage, replace the component.

If the damage indicates possible misalignment, check the pulley alignment. If the pulleys are not

properly aligned, check all fasteners for proper torque and that there are no loose or worn

components.

Note:

An automatic belt tensioner is being used; no manual tensioning of the belt is needed.

Replace the tensioner if it is showing signs of wear or damage.

Step

Action

WARNING

Disconnect the battery cable to prevent accidental startups.

1

Remove the 5 fasteners from the belt guard and remove the belt guard.

2

Use a 3/8” drive to rotate the tensioner to remove tension from the belt and

remove the belt.

3

Replace the drive belt with a new one, centering the belt over the pulleys.

4

Reinstall the belt guard and attach the battery cable.

Remove Fasteners (5X)

Us 3/8" Drive to

Rotate Tensioner

Check the drive belt for signs of cracks, glazing, missing or damaged ribs. If the drive belt is

damaged, install a new belt. Reference

Figure 6-4 Replacing Compressor Drive Belt

Table 6-9 Replacing the Compressor Drive Belt

Figure 6-4 Replacing Compressor Drive Belt

Summary of Contents for 60800N

Page 1: ...CRACK VAC MODEL 100G Operator Parts Manual 26627N Revision O ...

Page 3: ...Crack Vac Model 100G Manual Revisions Revision Date ...

Page 4: ...CRACK VAC MODEL 100G with COMPRESSOR P N 60900N CRACK VAC MODEL 100G P N 60800N ...

Page 10: ......

Page 12: ......

Page 18: ......

Page 22: ......

Page 40: ......

Page 77: ......

Page 78: ... 2020 Crafco Inc ...