Crack-Vac Model 100G Manual

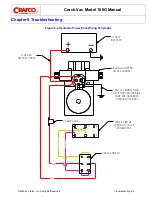

Chapter 8 Troubleshooting

©2020 by Crafco, Inc. All Rights Reserved

Troubleshooting 8-2

Problem

Possible Cause

Remedy

Engine will not start.

Inadequate supply of fuel to

carburetor.

•

Check fuel valve and lines, fuel

filter and fuel pump. See

Engine Operators Manual.

Starting with pressure in the

compressor

•

Relieve pressure.

•

Check blowdown function.

Compressor temperature too

high.

•

Allow compressor to cool

•

Diagnose and repair.

No Spark

•

Check electric system for

defective wires, switches, etc.

See Engine Operators Manual.

Battery discharged.

Charge or replace battery. See

Battery Recharging

(compressor battery)

Starter problems.

•

Repair or replace starter. See

Engine Operators Manual.

Engine air intake restricted.

•

Replace filters.

Engine Stalls

Compressor pressure set

too high.

•

Lower compressor air pressure

to 150 psi.

Operating at too high of an

elevation.

•

Install high altitude carburetor

kit. See Engine Operators

Manual.

Engine stalls when lowering

throttle speed.

•

Compressor enable switch left

in on position. Switch to off

before lowering speed.

Low engine oil.

•

Add oil.

Engine air intake restricted.

•

Replace filters.

Excessive oil in the air

Clogged scavenge tube or

fitting.

•

Clean or replace.

Coalescing separator failure.

•

Replace coalescing filter.

Compressor oil overfilled.

•

Reduce oil level. Check oil

level with equipment on level

ground.

Operating angle more than

15° from horizontal.

Reduce operating angle.

Incorrect startup/shutdown

procedures.

Observe startup/shut down

procedures. See

Table 8-2 Trouble Shooting Guide Compressor System

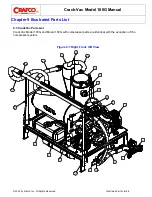

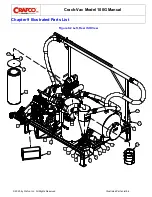

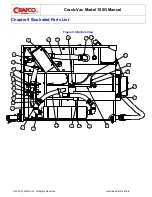

Summary of Contents for 60800N

Page 1: ...CRACK VAC MODEL 100G Operator Parts Manual 26627N Revision O ...

Page 3: ...Crack Vac Model 100G Manual Revisions Revision Date ...

Page 4: ...CRACK VAC MODEL 100G with COMPRESSOR P N 60900N CRACK VAC MODEL 100G P N 60800N ...

Page 10: ......

Page 12: ......

Page 18: ......

Page 22: ......

Page 40: ......

Page 77: ......

Page 78: ... 2020 Crafco Inc ...