Crack-Vac Model 100G Manual

Chapter 5 Operating Instructions

©2020 by Crafco, Inc. All Rights Reserved

Operating Instructions 5-6

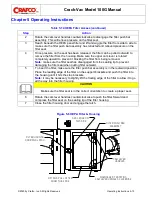

5.3 Starting the Compressor Engine

Step

Action

1

Relieve all pressure from the system by opening the air supply valves and closing

them once all pressure is relieved. Make sure the compressor enable switch is in

the off position. This will aid in starting the engine with the compressor being in an

“unloaded state”.

2

To start engine, place the throttle control midw

ay in the “slow” position, and place

the choke control into the “on” position.

3

Start the engine by activating the key switch. Release the switch as soon as the

engine starts.

Note:

Do not crank the engine continuously for more than 10 seconds at a time. If

the engine does not start, allow a 60 second cool down period between starting

attempts. Failure to follow these guidelines can burn out the starter motor.

Note:

Upon start-up a metallic ticking may occur. This is caused by the hydraulic

lifter leak down during storage. Run the engine for 5 minutes. The noise will

normally cease in the first minute. If noise continues, run the engine at mid throttle

for 20 minutes. If noise persists, take the engine to your local Kohler Service

Engine Dealer.

Note:

If the engine develops sufficient speed to disengage the starter but does not

keep running (a false start), the engine rotation must be allowed to come to a

complete stop before attempting to restart the engine. If the starter is engaged

while the flywheel is rotating, the starter pinion and flywheel ring gear may clash,

resulting in damage to the starter.

CAUTION

If the starter does not turn the engine over, shut off starter immediately. Do not

make further attempts to start the engine until the condition is corrected. Do not

start using another battery. See your Kohler Engine Service Dealer for trouble

analysis.

4

For a Cold Engine: Gradually return the choke control to the “off” position after the

engine starts and warms up. The engine/equipment may be operated during the

warm-up period, but it may be necessary to leave the choke partially on until the

engine warms up.

5

For a Warm Engine: Return the choke to “off” position as soon as engine starts.

6

Black smoke from the exhaust and a rough running engine usually indicate over-

choking.

7

Allow the engine to warm up at low idle for a few seconds.

Note

: Upon engine starting, the compressor will only build pressure to 50 psi. Do

not engage the compressor enable switch when the compressor is in low idle.

Doing so will cause the engine to stall.

8

Increase engine speed to full throttle.

9

Place the compressor enable switch in the on position. The compressor will build

pressure to 150 psi. The system is now ready for operation.

Table 5-4 Starting the Compressor Engine

Summary of Contents for 60800N

Page 1: ...CRACK VAC MODEL 100G Operator Parts Manual 26627N Revision O ...

Page 3: ...Crack Vac Model 100G Manual Revisions Revision Date ...

Page 4: ...CRACK VAC MODEL 100G with COMPRESSOR P N 60900N CRACK VAC MODEL 100G P N 60800N ...

Page 10: ......

Page 12: ......

Page 18: ......

Page 22: ......

Page 40: ......

Page 77: ......

Page 78: ... 2020 Crafco Inc ...