Operating Instruction

Spindle lifting system SL/SM 13xx with SCT iSMPS

Document no : B-00361

Edition 2020 06

Operating instruction EN

Copyright by Ergoswiss AG

25/27

10

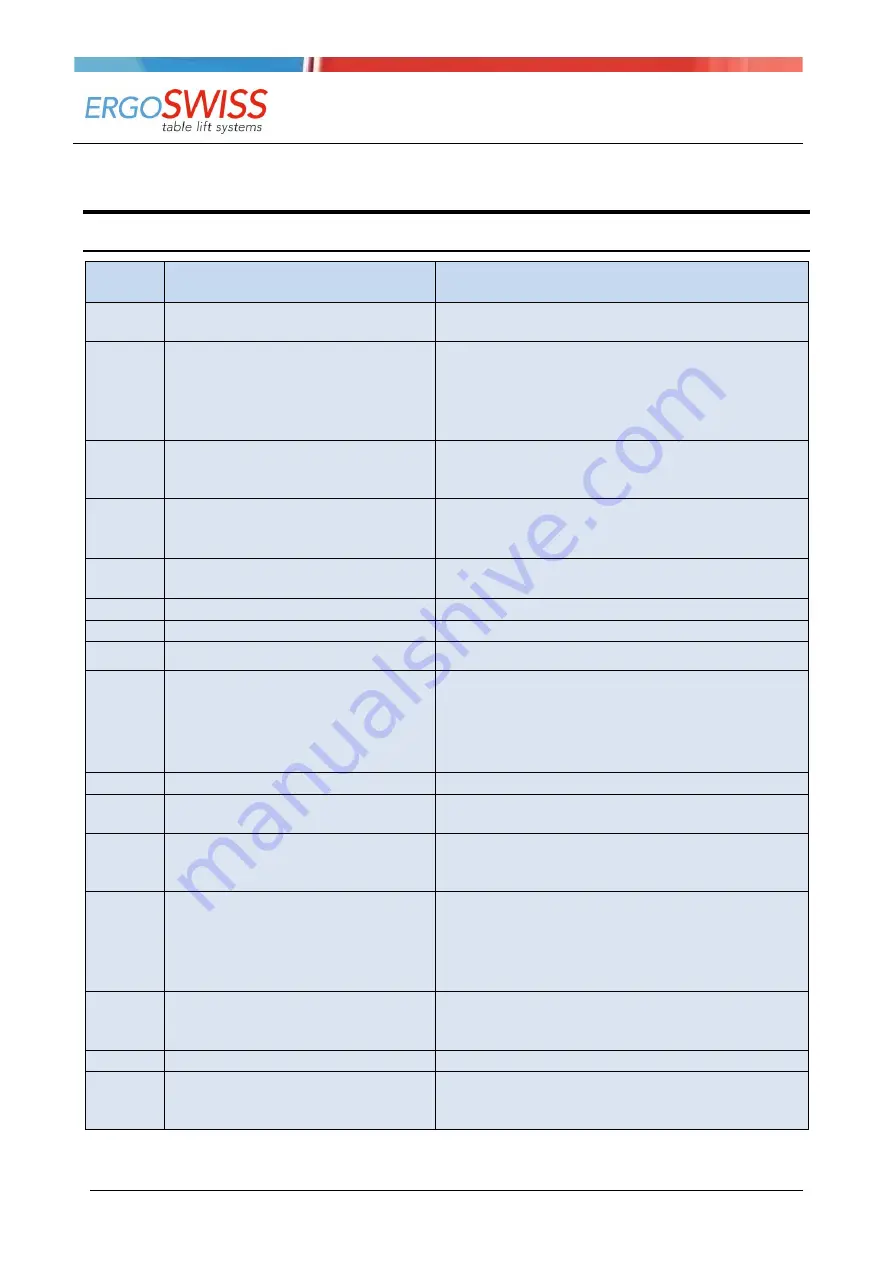

Error codes and trouble shooting

10.1

Error codes on the display

3-way

display

Description

Trouble shooting

E 60

Motor voltage supply below the per-

missible minimum

Check power supply. Connect power cable

E 61

Total current has exceeded the pro-

grammed limit

System overloaded

→

remove load from system

System jammed

→

remove jammed object

Motor not connected correctly

→

connect motor ca-

ble

E 62

User’s input is invalid (Container

-Stop

or Shelf-Stop cannot be set)

Container-Stop must be defined under the Shelf-

Stop, or Shelf-Stop must be defined above the Con-

tainer-Stop (see chapter 5.3)

E 63

Inconsistent or damaged

Motor control parameters recognized

Reprogram the control box

→

Contact technical support

E 64

Tilt sensor has been triggered

(Inclination too high)

1) Undo the tilt. (e.g. drive in the opposite direction)

2) Reset (see chapter 5.8)

E 65

Movement blocked (child lock)

See chapter 5.4

E 66

Safety strip was triggered

Remove jammed object

E 69

Safety strip missing

Connect or replace the safety strip

E 6F

Lifting movement monitoring

System overloaded

→

remove load from system

System jammed

→

remove jammed object

Motor not connected correctly

→

connect motor ca-

ble

E 71

Hall sensor -> wrong motor direction

Contact technical support

E 73

Motor missing -> no electricity

Check whether all motor cables are plugged in cor-

rectly

E 74

Sync cable not recognized

Check whether SYNC cables are plugged in

and then reset the control box to factory settings

(see chapter 5.7)

E 78

Overcurrent on a motor

System overloaded

→

remove load from system

System jammed

→

remove jammed object

Motor not connected correctly

→

connect motor ca-

ble

E 79

Sync error

(Connection error)

Check whether SYNC cables are plugged in

and then reset the control box to factory settings

(see chapter 5.7)

E 7A

Position difference of the motors

Reset (see chapter 5.8)

E 7C

The control box has the slave role.

Engine setting commands are not per-

mitted.

Reset to factory settings (see chapter 5.7)