Replacement of a surface mounted IC is best completed

using a hot-air soldering system. The IC can easily be re-

moved and installed using hot air. See the manufacturers

instructions for complete details on tip selection and other

operating instructions unique to your system.

If a hot-air system is not available, the service technician

may wish to clip the pins near the body of the defective IC

and remove it. The pins can then be removed from the PWB

with a standard soldering iron and tweezers and then the new

IC can be installed. It should not be necessary to "tin" any of

the IC pins before the installation process.

MODULE REPLACEMENT

The modules, all of which are located on the RF Board,

are very reliable devices. Before replacing any of the mod-

ules, check the associated circuitry thoroughly to insure there

is not a problem elsewhere. If replacement is necessary,

follow the below procedures.

All of the component lead holes for the modules on the

RF Board are plated through from the top to the bottom of

the board. This allows for easy removal and replacement of

the modules as long as appropriate soldering techniques are

observed. Always observe static precautions when handling

the board.

To remove the PA module, it is first necessary to remove

the hardware which supports it. Two (2) Torx screws and a

support bracket secure the module to the eggcrate casting.

To remove a module, position the RF Board in a work

vise (face down, chip components up) and remove the solder

from the plated-through points at the appropriate pins. If a

hot-air system is employed, use an appropriate tip that will

localize the heat on the pins and not on surrounding chip

components. Solderwick

or a vacuum de-soldering iron

will also remove the solder if a hot-air station is not available.

When all solder has been removed or liquefied, the module

should drop out of the eggcrate casting.

To install a module, clean any solder from the plated-

through holes and clean all flux from the board. Next, install

the replacement module making sure that all pins align in the

proper holes. Resolder the pins to the board. Clean the flux

from the board using an approved solvent. Clip any excess

lead length.

INTERNAL LITHIUM BATTERY

REPLACEMENT

All personality data is stored in RAM IC U1 on the

Control Board. This data includes TX and RX operating

frequencies, Channel Guard tones, CCT information, Track-

ing Data, etc.. The lithium battery on the Control Board

supplies keep-alive power to this RAM IC when the radio is

turned off. This battery should be changed every 3 to 5 years.

Before replacing the battery, copy the radio’s personal-

ity data to the PC computer. The battery can be replaced

without losing the personality data stored in the radio by

following the below procedure.

1.

Remove the Control Board. See the "DISASSEM-

BLY/REASSEMBLY" instructions for details. Use

caution when handling the board; do not short the con-

nections between the lithium battery, D2 and the RAM

IC. Also observe static handling precautions.

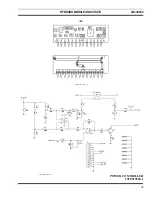

2.

Using clip leads, apply power (7.0 - 9.0 Vdc) to the

Control Board at the bottom mounting holes. OBSERVE

POLARITY. See Figure 12.

3.

Remove the plastic cover from the lithium battery. This

battery’s case is positive polarity, opposite of what

would be expected.

4.

Unplug and remove the battery from the support and

contact.

5.

Carefully install the new battery in the support, plugging

the negative terminal into the contact. Record installa-

tion date.

6.

Install the plastic cover over the new battery.

7.

Remove power from the board.

8.

Reassemble the radio and test for proper operation.

WEATHERPROOF INTEGRITY

The MTL radio is designed to meet the MIL-810C & D

environmental specifications. The internal circuitry is pro-

tected from moisture by appropriate seals. Rear Cover As-

sembly seals include the Front/Rear Cover Assembly gasket

and the antenna insert gaskets. Front Cover Assembly seals

include the speaker/microphone seal, the battery plate seal,

and the volume and channel control seals. The UDC/Monitor

Button/PTT Assembly is also designed to seal out moisture.

LBI-38632

26