RECEIVER ALIGNMENT

(Cont.)

RECEIVER ALIGNMENT

TEST EQUIPMENT REQUIRED (Or Equivalent)

1.

GE Test Set 4EX3A11, 4EX8K12, or 20,000 ohms-

per-volt millimeter with 1 volt scale

2.

AC Voltmeter

3.

FM Deviation Monitor

4.

Digital Voltmeter

5.

VOM

6.

RF Signal Generator (403-512 MHz)

7.

Frequency counter (Hewlett-Packard 5300B)

8.

Oscilloscope

9.

Audio Isolation Transformer (1:1) 19A116736P1 or

equivalent

10. 4 ohm 15 watt resistor

11. Tuning tool 19B800716P2

PRELIMINARY CHECKS AND ADJUSTMENTS

1.

Connect the black plug from the Test Set to the RF metering jack J101. Connect red system metering plug to J602, system

metering. Set Test Set to 1 volt scale. A 20,000 ohms-per-volt multimeter may be used when the GE Test Set is not

available.

2.

Preset C1-C7 to maximum height above top of tuning nut (10 mm above casting).

3.

Preset L509 to top of coil form and then turn clockwise 11 full turns.

4.

Preset L451 to top of coil form, then turn 15 turns clockwise.

5.

Preset L410, L411, L412, L507 and L508 to top of coil form and then turn clockwise 9 full turns.

6.

Apply power to radio and monitor the regulated 9 volt supply at J602-3. Adjust R703 if necessary to obtain 9

±

0.01 Vdc.

Use a digital multimeter.

ALIGNMENT PROCEDURE

NOTE

Refer to Figure 5 for location of tuning and adjustment controls.

NOTE

Before aligning the receiver or making any adjustments to the radio be sure that the output of the 9 volt regulator is set

for 9.0

±

0.1 Vdc.

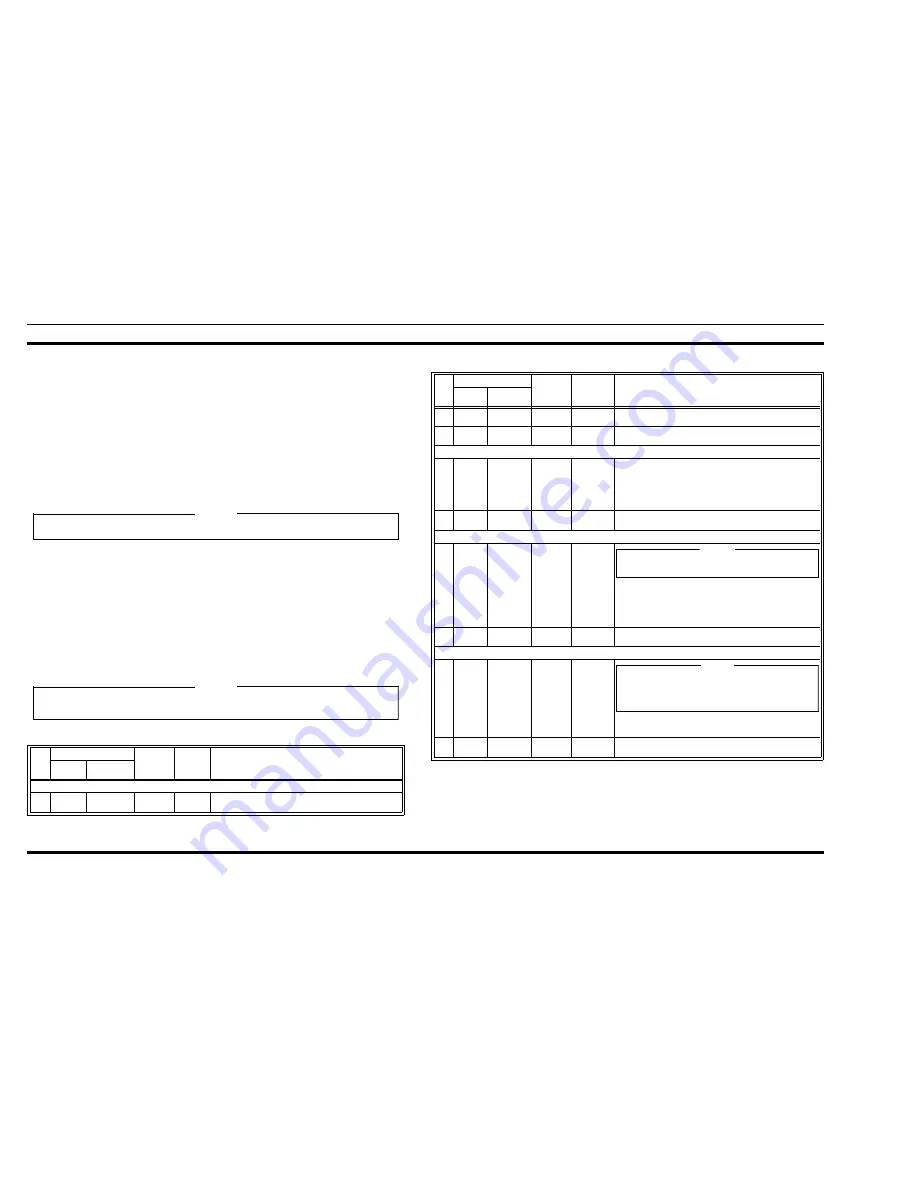

STEP

METERING POSITION

TUNING

CONTROL

METER

READING

PROCEDURE

GE TEST

SET

MULTIMETER

(- TO A-)

LOCAL OSCILLATOR-BUFFER INJECTION

1.

G

(RX INJ)

J101-4

L452

Peak

Select desired channel or center tune frequency. Set Test Set to 1 volt

scale and tune L452 for maximum reading on Test Set.

ALIGNMENT PROCEDURE (Cont.)

STEP

METERING POSITION

TUNING

CONTROL

METER

READING

PROCEDURE

GE TEST

SET

MULTIMETER

(- TO A-)

3.

G

(RX INJ)

J101-4

C7

Dip

Tune C7 for a dip in Test Set reading.

4.

H

(RX MIX)

J101-3

C6, C7

L452

Peak

Tune C6 for maximum. Sequentially retune L452, C6 and C7 until there is

no further increase in meter reading.

FRONT END ALIGNMENT

5.

D

(IF AMP)

J602-10

C3

MAX

Connect RF signal generator to antenna jack J2. Set frequency to desired

receive channel or center tune frequency. Set modulation frequency to 1 kHz

and deviation to 3 kHz. Set input level to -10 dBm (70 mV).

Tune C3 for maximum indication on meter while reducing the input level

of the signal generator as required to keep the IF AMP reading from

saturating. (0.6 V typical).

6.

D

(IF AMP)

J602-10

C1, C5

C2, C4

Peak

Peak C1, C5, C2, C4 in sequence while reducing output level of signal

generator to prevent saturation.

RF SELECTIVITY

NOTE

If the IF amplifiers have been aligned using the alternate sweep alignment

method, proceed to Step 9.

7.

D

(IF AMP)

J602-10

L508, L507

L410, L411

and L412

Maximum

(See

Procedure)

Select a center frequency channel. Apply an on-frequency signal with 1 kHz

modulation to antenna jack J2. Set deviation to 3 kHz. Reduce signal level

to approximately 75% of saturated level shown on Test Set meter. While

making the following adjustments keep the signal level below saturation.

Tune L508, L507, L412, L411 and L410, in that order, for a peak reading.

Repeak coils until no further improvement in meter reading is noted.

8.

D

(IF AMP)

J602-10

C1-C5

Maximum

Repeak C1-C5.

FM DETECTOR/AUDIO PREAMPLIFIER

NOTE

The audio output is a balanced bridge circuit and requires all test equipment

connected across the speaker leads to the both AC and DC isolated from

ground.

Connect test equipment as shown in Figure 5.

9.

L509

0.35 - 0.5

VRMS

Set signal generator output for 1000

µ

V. Set R629 and volume control to

the center position. Monitor the speaker outputs (J602-6, 7) with an AC

voltmeter. Tune quadrature coil L509 for a peak reading.

10.

R629

Adjust R629, audio preamplifier level for nominal 300 mV RMS at VOL/SQ

HI (J603-14).

(Cont.)

LBI-31511

LBI-31511

12

Summary of Contents for LBI-31511B

Page 15: ... 19D901350 Sh 1 Rev 10 RECEIVER AUDIO AND SQUELCH WAVEFORM CHECKS LBI 31511 LBI 31511 14 ...

Page 16: ... 19D900977 Sh 1 Rev 20 MECHANICAL LAYOUT LBI 31511 LBI 31511 15 ...

Page 17: ... 19D900977 Sh 2 Rev 14 MECHANICAL LAYOUT LBI 31511 LBI 31511 16 ...

Page 18: ... 19D900980 Sh 1 Rev 4 INTERCONNECTION DIAGRAM LBI 31511 LBI 31511 17 ...