4

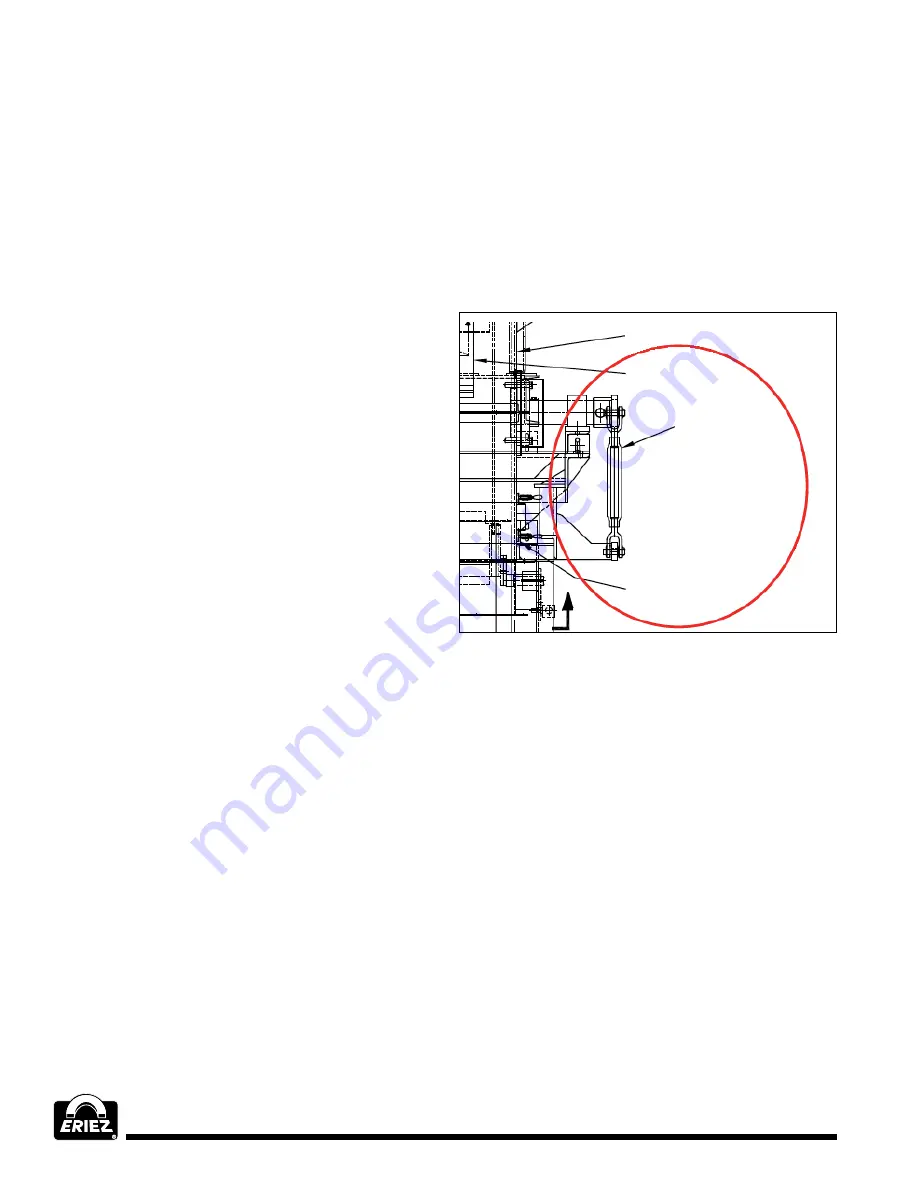

Figure 1

General

Magnetic drums with high peripheral shell speeds

were developed to satisfy a need for a dry magnetic

separator capable of processing large volumes of

relatively fine ferromagnetic particles (-1") (-25mm).

Units previously available did not provide high

capacity or efficiency. The DF High Speed Drum is

a highly efficient unit for processing large volumes

of material and producing high grade magnetic

concentrates or removing very fine, highly

magnetic particles for purification.

Capacity, grade and recovery are directly related

to the peripheral speed of the drum. For high

recovery of magnetics or purification of non-

magnetics coarser than 1/8" (3mm), the Model

DFA-10 at a relatively slow peripheral shell speed is

used. The DFA-25 is used at moderate speeds for

cobbing or roughing concentration jobs. When a

very high grade, finished magnetic concentrate is

desired, the DFA-50 is used at a high shell speed.

Description of Equipment

Eriez DF High Speed Drum Separator consists of

a rotating drum shell within which is a permanent

magnetic element attached to a stationary support

and shaft. The magnetic element covers an

approximate 210° arc. Depending on the

application the drums are furnished with an A10,

A25, or A50 agitating magnetic element or with an

RE (rare earth) magnetic element. A 1-1/2" (38mm)

diameter hole and magnetic turnbuckle is drilled

through the shaft at the side opposite the motor

drive for positioning of the magnetic element. A

turnbuckle is currently used to make element

adjustments. (See Figure 1).

The shell is made from 1/8" (3mm) thick 304

stainless steel and typically has a 1/8" (3mm) thick

abrasion resistant rubber liner. Drum heads are

high strength aluminum alloy castings. Bearings

are completely sealed oversized antifriction type

for durability and trouble free operation.

A rectangular shaped dust-tight housing with

provision for dust collector connections is furnished

within a heavy steel angle superstructure. Housing

end panels have ¼" (6mm) thick abrasion resistant

rubber lining to reduce wear. An adjustable splitter

is furnished to separate the magnetic and

nonmagnetic fractions.

For periodic inspection of the housing interior

and the drum shell, a large hinged inspection

panel is provided.

A feeder is normally required for efficient operation

of the DF drum. An Eriez vibrating feeder is

recommended for most applications.

A TEFC motor and drive is furnished as standard

for all applications. The drive consists of a chain

and sprockets with an oil tight chain guard. A VFC

is recommended to vary the drum speed.

Installation Instructions

Installation is very straightforward. The system has

been assembled and has run at our factory to assure

quality. The DF drum separator comes completely

assembled. The vibratory feeder and control has

to be mounted to the drum housing per the outline

drawing for the particular order. Attach the feeder as

shown on the drawing and wire the control per the

included electrical schematic. All dust boots must be

attached and loose enough to prevent binding of the

feeder. Make sure the Vibratory Feeder has the

proper deflection. (See feeder IOM elsewhere in

this manual for deflection).

Dust extraction couplings are on the top cover of the

drum housing for use by the customer. If using Rare

Earth magnet material, avoid moisture weeping in

to the magnetic element. It would cause irreparable

harm. Avoid exposing the standard Rare Earth

magnet material to high temperature. The standard

circuits can only handle 150°F (65°C). Other circuits

are available to handle higher temperatures.

Inspection door

Mild steel housing

dust-tight construction

Inspection door

Magnet

adjustment arm

A