Sump Cleaner

15

3. Discharge Operation:

To return filtered,

chip-free coolant to the machine, to wash down

the machine, or to discharge coolant into your

recycling or disposal system:

A. Close the suction inlet valve completely.

B. Close the vacuum valve completely.

C. Connect the compressed air supply line to the

compressed air inlet. (This compressed air

inlet is equipped with a preset, nonadjustable

pressure reducing regulator to lower the air

pressure to 7 PSI. A 15 PSI safety “POP-

OFF” valve in this same line acts as a back

up to prevent over-pressurizing the sump

cleaner tank). Turn on the air supply by

opening discharge valve.

D. Depress the discharge hose nozzle handle.

E. When discharging operation is complete,

turn off the compressed air supply by

closing discharge valve and close the

discharge nozzle.

F. Discharge valve is a three-way ball valve that

will depressurize the sump cleaner tank when

fully closed. To avoid possible injury, do not

leave the sump cleaner pressurized.

4. To empty the filter basket:

A. Remove tower lid.

B. Attach lifting device to basket rings.

CAuTION

: All components used to lift basket

(steel cable, hooks, crane, etc.) must have a

minimum capacity of 1000 pounds.

Operation Requirements

(cont.)

C. To avoid the basket binding in the tower

during removal, position the lifting power

source (e.g. crane) directly over the center

of the basket.

D. Hoist the basket. Keep hands and fingers

clear. If the basket is binding and unable to

lift freely, return (lower) the basket to the sump

cleaner tower. Reposition the lifting device so

that the basket exits the center of the tower.

E.

DO NOT TOuCH BASKET DuRING

REMOVAl.

F. Position the basket over the waste receptacle.

G. Standing clear, open the basket trapdoor by

pulling the locking pin cable.

H. Once the basket is empty, carefully close the

trapdoor and slide the locking pin into place.

I. Check the filter sleeve. If it is badly soiled

or clogged, turn it inside out and wash it

in a suitable cleaner. Replace filter when

necessary. (Refer to the MAINTENANCE

section of this manual.)

J. Inspect the basket hoisting rings for signs

of rust. Replace the basket with a new one

if the rings are heavily corroded.

K. Keeping hands and fingers from under the

basket lip, reseat the basket in the tank and

clamp down the tank lid.

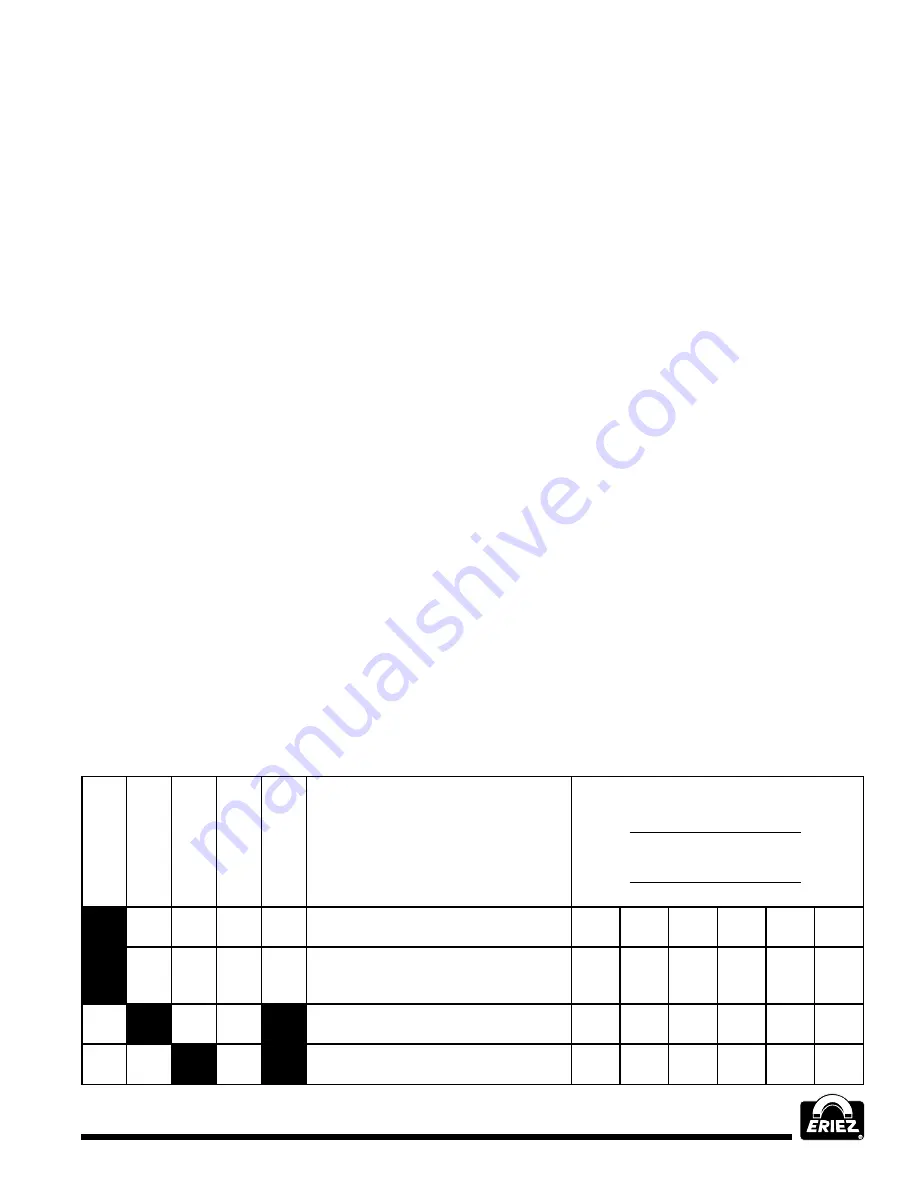

W

e

e

k

l

y

M

o

n

t

h

l

y

6

M

o

n

t

h

s

100

H

o

u

r

s

12

M

o

n

t

h

s

Maintenance

Schedule for

Air Venturi

Sump Cleaners

Maintenance Log

Date placed into service:

Record date of service below:

Inspect suction and discharge hoses;

replace as needed

Inspect filter basket sleeve; replace

as needed. Inspect basket lifting

rings for corrosion

Inspect tank for sludge buildup;

clean as needed

Grease wheels and casters;

use No. 2 bearing grease

Summary of Contents for FJ-310A

Page 27: ...Sump Cleaner 27...