Installation & Operation Manual

Proven Quality since 1892

ECON check valves Fig. 2630-2631

www.eriks.com

Rev. 0

7. Installation

During the assembly of the ECON ball check valves, the following rules should be observed:

Make sure before an assembly that the valves were not damaged during the transport or

storage.

Make sure that the applied valves are suitable for the working conditions, medium used in

the plant and the right system connections, according to pressure and temperature limits.

When installing the ball check valves, ensure that the seat and the flange faces are

clean.

When valves are provided with lifting lugs, plates or eye nuts, these must be used to lift

the valve.

All special packaging material must be removed.

To ensure you use the correct sealing it is important to select the correct type of gasket

for the medium concerned, gaskets with the correct flange size must be used.

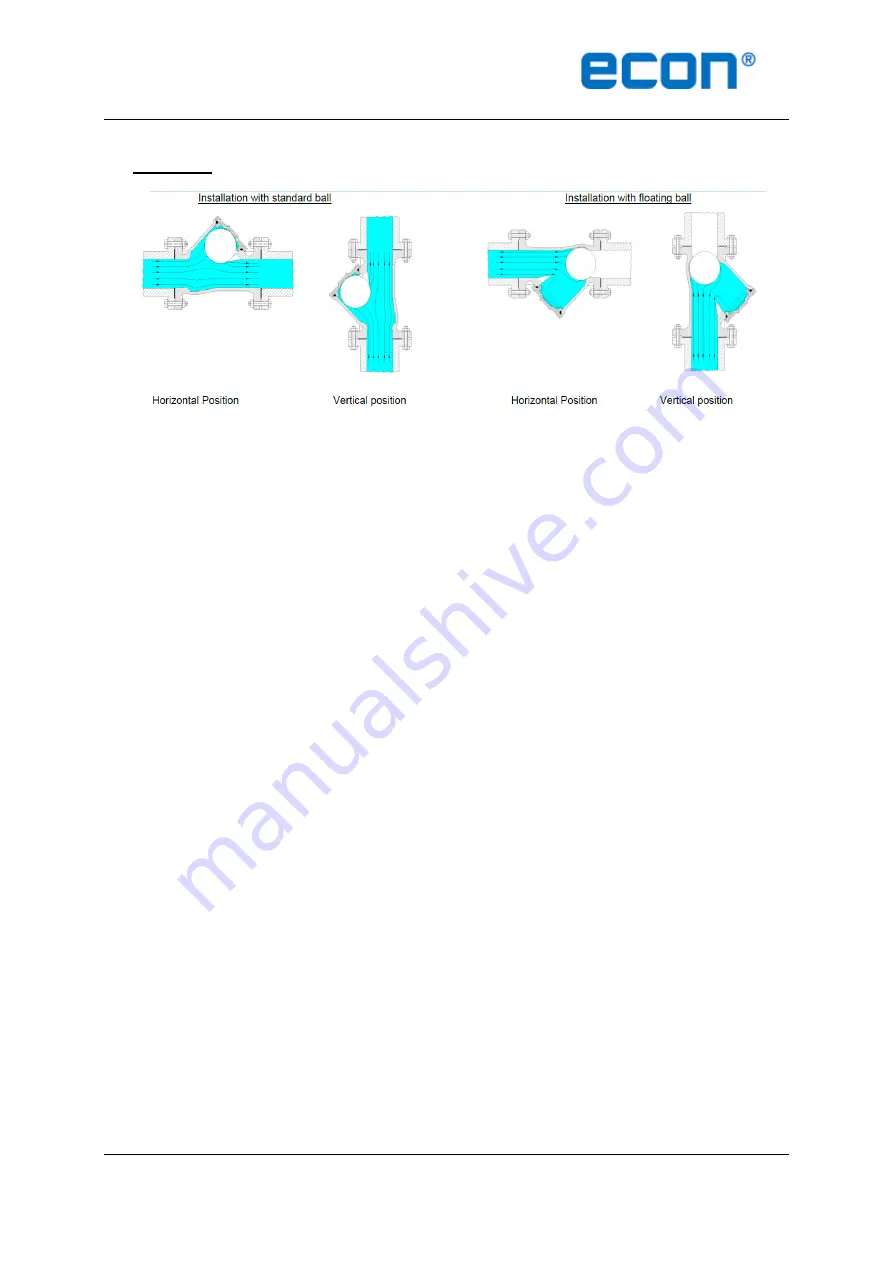

In horizontal pipelines the valve must be installed so that the bolted cover is facing

upward. (for version with sinking ball)

The valve must be installed with the direction arrow on the body coincident with the

direction of flow in the pipeline. For vertical pipelines the flow direction should only be

upwards.

Immediately prior to valve installation, the pipeline should be checked for cleanliness and

free of debris.

Valve end protectors should only be permanently removed prior to installation.

Place valve between pipe flanges, and insert the bolts.

Tighten bolts loosely.

Tighten bolts in a diagonal sequence to ensure flanges are pulled up parallel.

Finally tighten bolts to correct torque levels

Before plant startup, especially after repairs carried out, flash out the pipeline.

After installation it is necessary to check the valve operation and tightness of all

connections. A tightness test should be carried out.

Install pipelines so that damaging transverse, excessive vibrations, bending and tensional

forces are avoided.