Installation & Operation Manual

Proven Quality since 1892

ECON check valves Fig. 2630-2631

www.eriks.com

Rev. 0

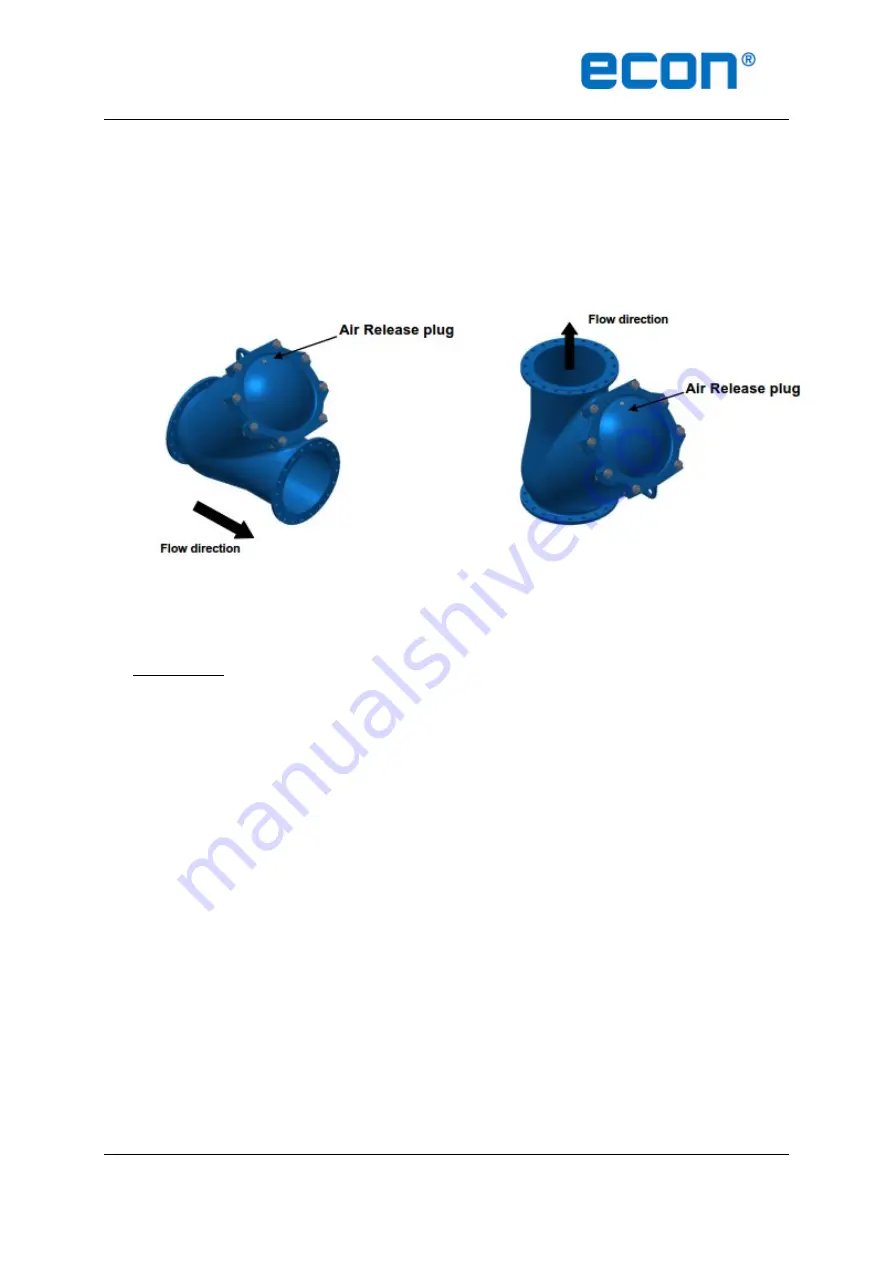

Valves with air release plug.

The ball check valves DN400 and above are foreseen of an air release plug for elimination of the

accumulated air in order to avoid damage during start up. This plug must always be located on

the highest part of the valve. See figures below depending on vertical or horizontal installation. If

not specified by the customer, the plug is installed standard for horizontal pipeline installation. If

valves are installed in vertical pipeline (and not specified in the PO), the bonnet must be turned

180

°.

To eliminate the air proceed by unscrewing the plug in order to release the accumulated air until

the fluid is coming out. The plug is auto blocked and cannot be unscrewed totally. If the plug is

damaged or blocked, proceed disassembly of the bonnet as indicated in previous content. It is

recommended to clean the plug when bonnet is disassembled for maintenance.

8. Maintenance

Before starting any service jobs, make sure that the medium supply to the pipeline is cut off,

pressure was decreased to ambient pressure, the pipeline is completely cleaned and ventilated

and the plant is cooled down. Always keep safety instructions in mind and take all personal safety

precautions.

ECON ball check valves do not require any special maintenance. In certain cases it might be

possible to replace or clean the internals (ball , O-ring), caused by natural wear of the components

or the accelerated wear as cause of the non-appropriate installation in the pipeline (such like not

respecting the precautions for assembly in pipeline or the application with very corrosive or

aggressive fluids).

During maintenance, the following rules should be observed:

-

always keep personal safety precautions in mind and always use appropriate protection

e.g. clothing, masks, gloves etc.

-

be alert that the temperature still can be very high or low and can cause burns.

-

check the valve on all possible leaking possibilities.

-

check if all bolts and nuts, are still fastened.

-

check if the ball still functions in a proper manner.

-

the thickness of the body must be checked to ensure safety operation at an interval of at

least three months.