Installation & Operation Manual

Proven Quality since 1892

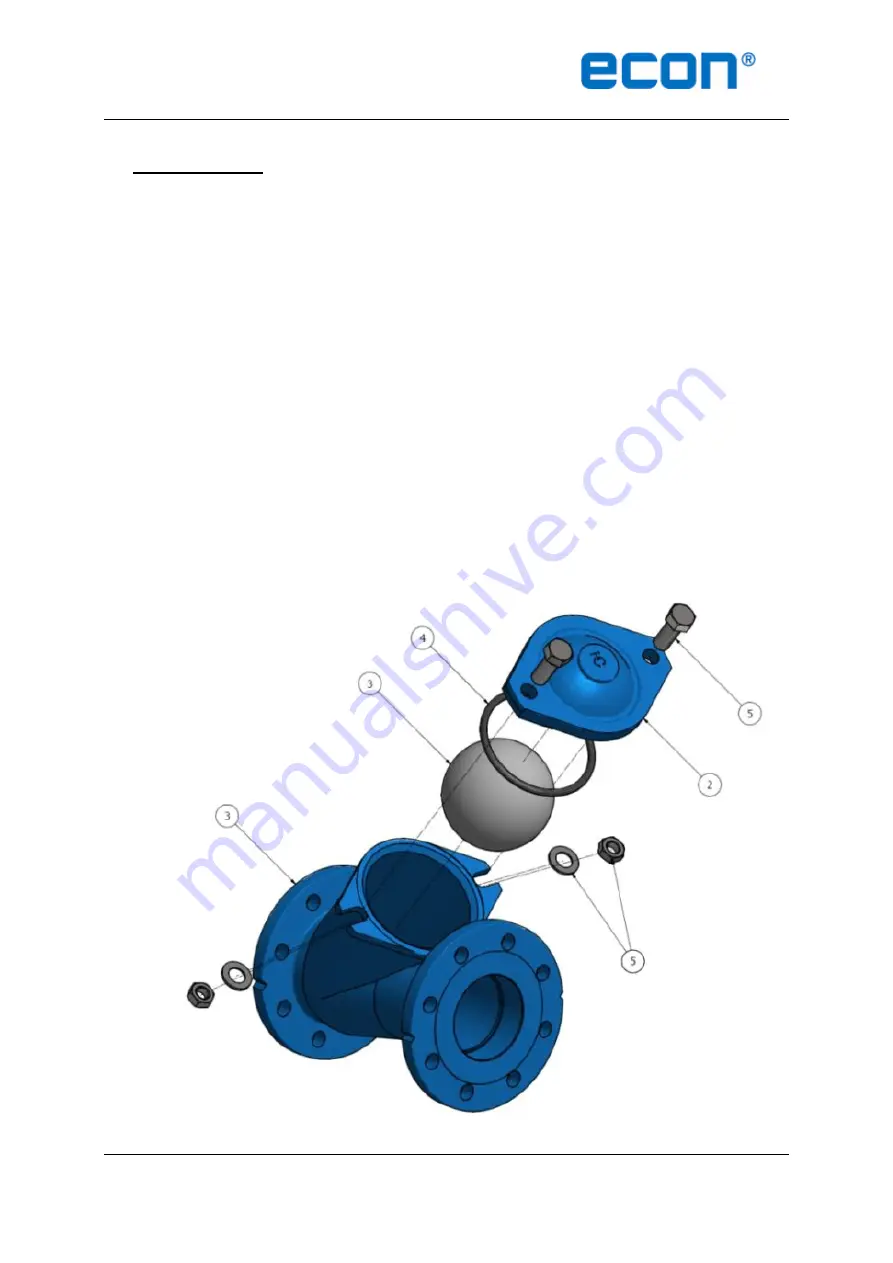

ECON check valves Fig. 2630-2631

www.eriks.com

Rev. 0

9. Service and repair

All service and repair jobs should be carried out by authorized staff, using suitable tools and user

shall use valve ball, O-ring, bolt and nut of the same size and material as the original one.

-

weld repair and drilling of the valve is forbidden.

-

it is forbidden to replace the bolt, nut or packing when the valve is under pressure.

-

tighten the hexagon nuts evenly crosswise in the therefor standard order.

-

after replacement of the ball, O-ring, bolts or nuts, it is necessary to check the valve

operation and tightness of all connections. A tightness test should be carried out.

-

after installation, the valve should be checked and maintained periodically at least every

3 months, depending on the medium.

Replacement and/or cleaning of ball check valve components.

-

Loosen the bolts of the bonnet (5) in a cross sequence and with correct tools in order to

avoid damage to the components

-

Proceed by lifting the bonnet. For big sizes it is recommended to use elevation equipment.

If the bonnet contains a lifting or is foreseen of a threaded hole to fix a lifting lug, than this

must be used to lift the bonnet. If the bonnet is not foreseen of lifting lugs it is

recommended to use straps passing the holes of the bolting

-

Take out the O-ring (4) for sealing the bonnet and proceed with cleaning or replacement.

In order to assure the tightness after assembly, we recommend to replace the O-ring

every time the bonnet is being disassembled.