Installation & Operation Manual

Proven Quality since 1892

ECON check valves Fig. 2630-2631

www.eriks.com

Rev. 0

-

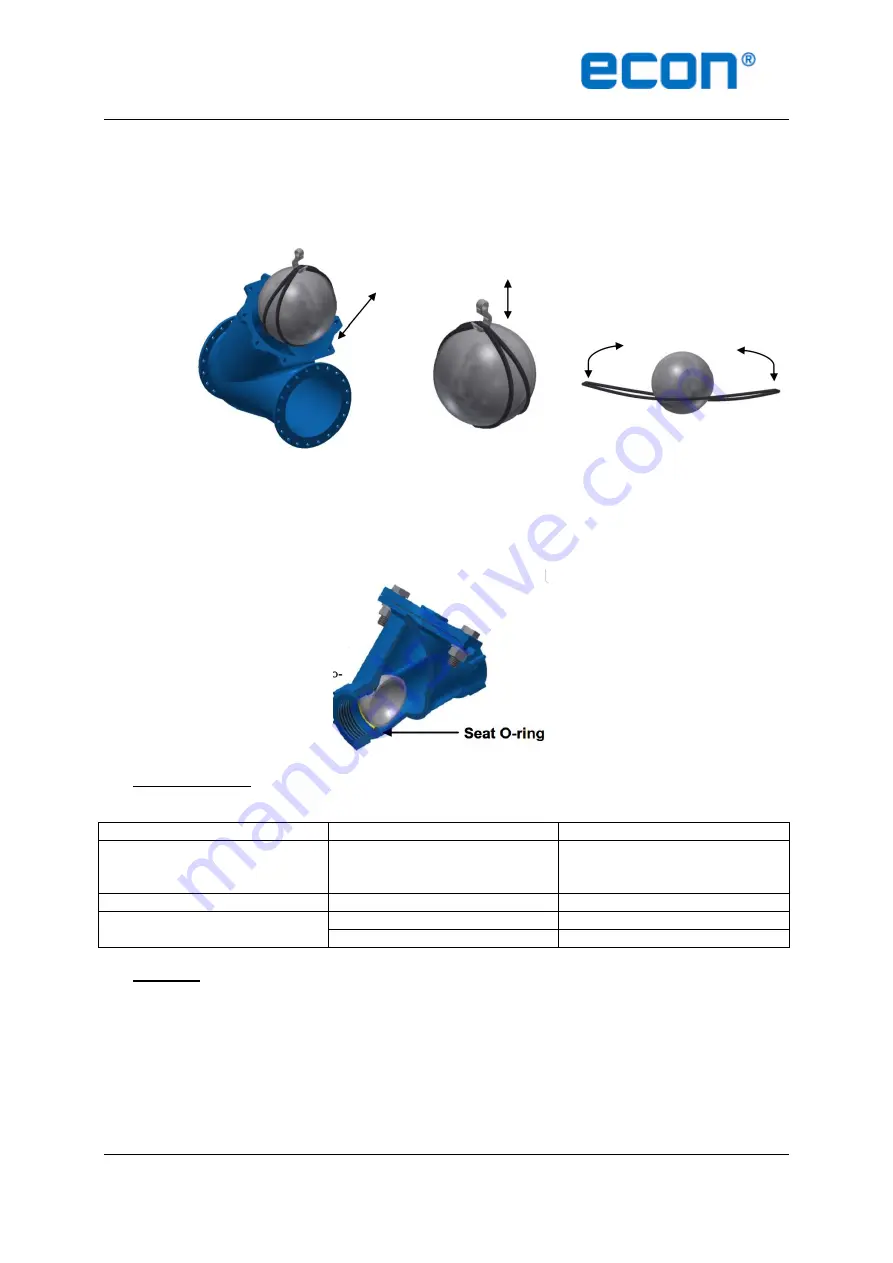

Take out the ball (3) to proceed cleaning or replacement. Be careful not damaging the ball

or coating during replacement or cleaning when using non compatible products. For the

bigger sized valves it is recommended to use elevation equipment and straps like shown

in below figures. Verify if the ball is not damaged at any point. In case of any damage, we

recommend to replace the ball.

-

Clean the area where the ball is located when closed and also the valve passage must be

clean

-

Proceed assembly of the valve, introduce the ball, place the O-ring (4) for tightness and

the bonnet (2) centered correctly in the opening of the body (1), take special care that the

O-ring is placed in correct position in order to avoid damage when fixing the bolts. Finally

start fixing the bolts (5) in a cross sequenced order.

10. Troubleshooting

It is essential that the safety regulations are observed when identifying the fault.

Problem

Possible cause

Corrective measures

No flow

Valve is installed in the wrong

way

Arrow of flow direction has to

run in the same direction as the

flow itself

Little flow

Piping system clogged

Check piping system

Leakage across valve seat

Seat or ball is damaged

Replace the seat or ball

Foreign matter is in the valve

Clean the valve.

11. Removal

All dismantled and rejected valves cannot be disposed with household waste. The valves are

made of materials which can be re-used and should be delivered to designated recycling centers.