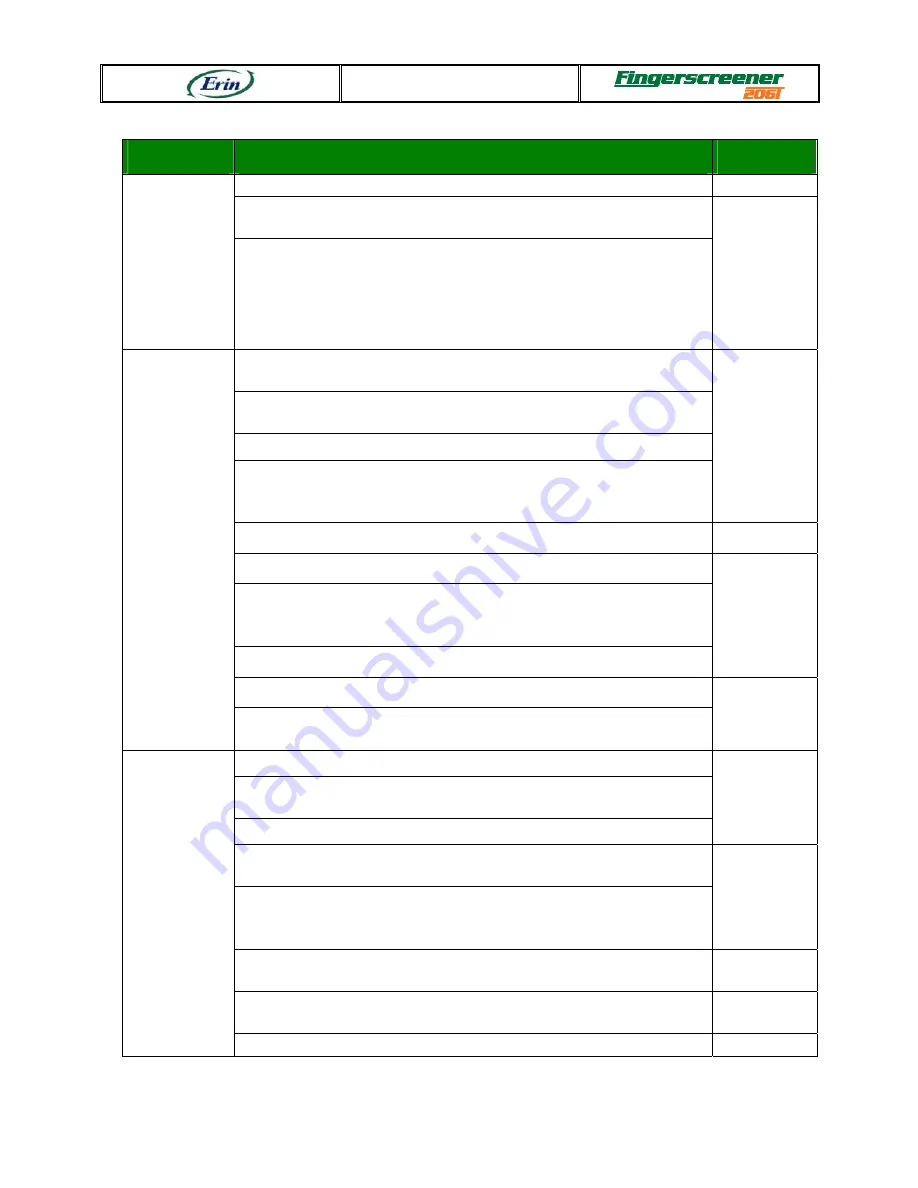

Maintenance

Rev: 0-3 (international, serial no. 3010)

- 5-7 -

May 2006

Part

Action

Frequency

Check all moving parts and grease if necessary.

Monthly

Inspect all mechanical parts for defects or wear. Change parts if

necessary.

Screen Box

If necessary, take bearings off the machine for inspection. Clean

and grease bearings before installation (every 2 000 hours only).

The Screen Box bearings have a limited lifetime and must be changed after

8 000 hours of work. Refer to Screen Box bearing installation instructions at

the end of chapter 4.

This step is recommended by bearings

manufacturers but is not mandatory.

Yearly

Remove residual material, clean out dirt and pressure wash if

necessary.

Track belt and adjust tension if necessary

(see

section 4.5

for

instructions)

.

Adjust skirting if necessary.

Check V-plow scraper skirting and change it if there is ¼ inch or

less rubber left over the metal support. Skirting can be reversed

once before being changed.

Daily

Check rollers for proper functioning. Change if necessary.

Weekly

Check the condition of all hydraulic motors.

Grease bearings if necessary. Make sure the grease fitting is

clean before doing this operation.

Do not over grease the

bearings

(1 grease gun shot).

Grease pins and pivots.

Monthly

Inspect all mechanical parts for defects or wear.

Conveyors

Check the normal wear and tear of the belts. Change or repair

them if necessary.

Yearly

Make sure that all safety devices work properly.

Remove accumulated debris and dirt that can interfere with the

machine’s proper operation.

Remove debris from area around hydraulic cylinders and levers.

Daily

Grease raising system pins and pivots (any kind of lithium-based

grease is good).

Check track tension every day for the first two weeks of use.

Refer to the manufacturer file at the end of this manual for more

details.

Daily

Lubricate all hinges and door handles (Power Pack access

panel). General purpose lubricant is good.

Weekly

Check all bolts and tighten any loose ones after the first 100

hours of operation.

Monthly

Main Frame

Clean electrical panel from accumulated dirt or dust.

Yearly

Summary of Contents for Fingerscreener 206T

Page 73: ......

Page 79: ......

Page 81: ......

Page 83: ......

Page 85: ......

Page 87: ......

Page 90: ......

Page 93: ......

Page 96: ......

Page 100: ......

Page 102: ......

Page 103: ......

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 131: ...7C 13 3 B 31 C 142 H6 HU VS MH HYDROMATIK A2FE 125 61W PZL100 MT713C033 23 06 2006 ...