# VSH400PLC090909

- 23 -

9. MAINTENANCE AND OPERATION RECOMMENDATIONS

The station should be cleaned every day – this considerably affects its

durability.

Maintain order at the work place. This will limit mechanical damage.

Drawers are for keeping tools – do not store materials in them.

Change and replenishing hydraulic oil:

Dismantle the (right) side shield of the station.

Change the oil as described in the technical documentation of the Hydraulic

generator (Chapter 9)

Install the station shield.

Lubrication of the lifting screw of the bending-punching segment (if needed).

Remove the crank S1

Unscrew the shield.

Lubricate the screw with grease ŁT-46

Fix the shield.

Install the crank S1

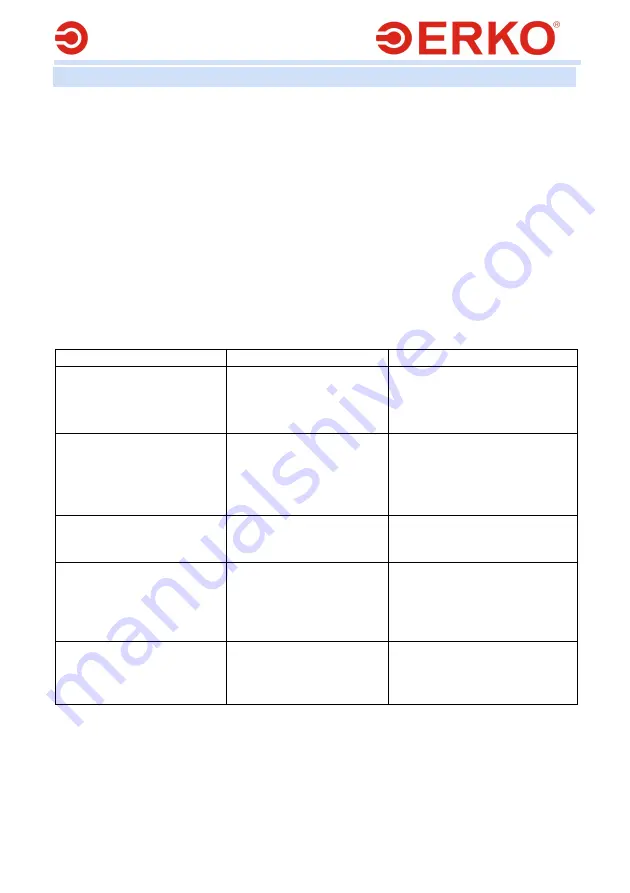

Defects

Problem

Cause

Solution

1. The power supply

control lamp is not lit after

the machine is switched

on

a. No power supply.

b. Absence of 1 phase

c.

Voltage drop to 175

V/phase

Check the source of power

2. The machine switches

off during operation

a. Phase decay on the

engine

b. The engine fuse

action

c.

Power decay.

Check the source of power

and engine fuse

3. Loud pump operation

without servo-motor stick-

out

a.

electrical valve

defect

Contact the service

4. Loss of reference points

Permanent or temporary

absence of

communication between

the encoders and the

controller

Restart the station and look

for them again

Contact the service

5. Incorrect readings on

the control panel

Disturbed

communication between

the executive elements

and the control panel

Restart the station.

Contact the service