Erme AG

Control/operation | 7

Table models professional

45 / 66

7.8 Preparing the machine for injection of inert gas

DANGER

There is a risk of fire due to use of the wrong inert gas.

There is a risk of fire when injecting gas with oxygen.

4

By default, only nitrogen or a mixture of nitrogen and carbon

dioxide may be used as an inert gas.

4

Oxygenated gases (over 21%) may only be used after taking

special safety measures (special vacuum pump, special oil and

safety valves).

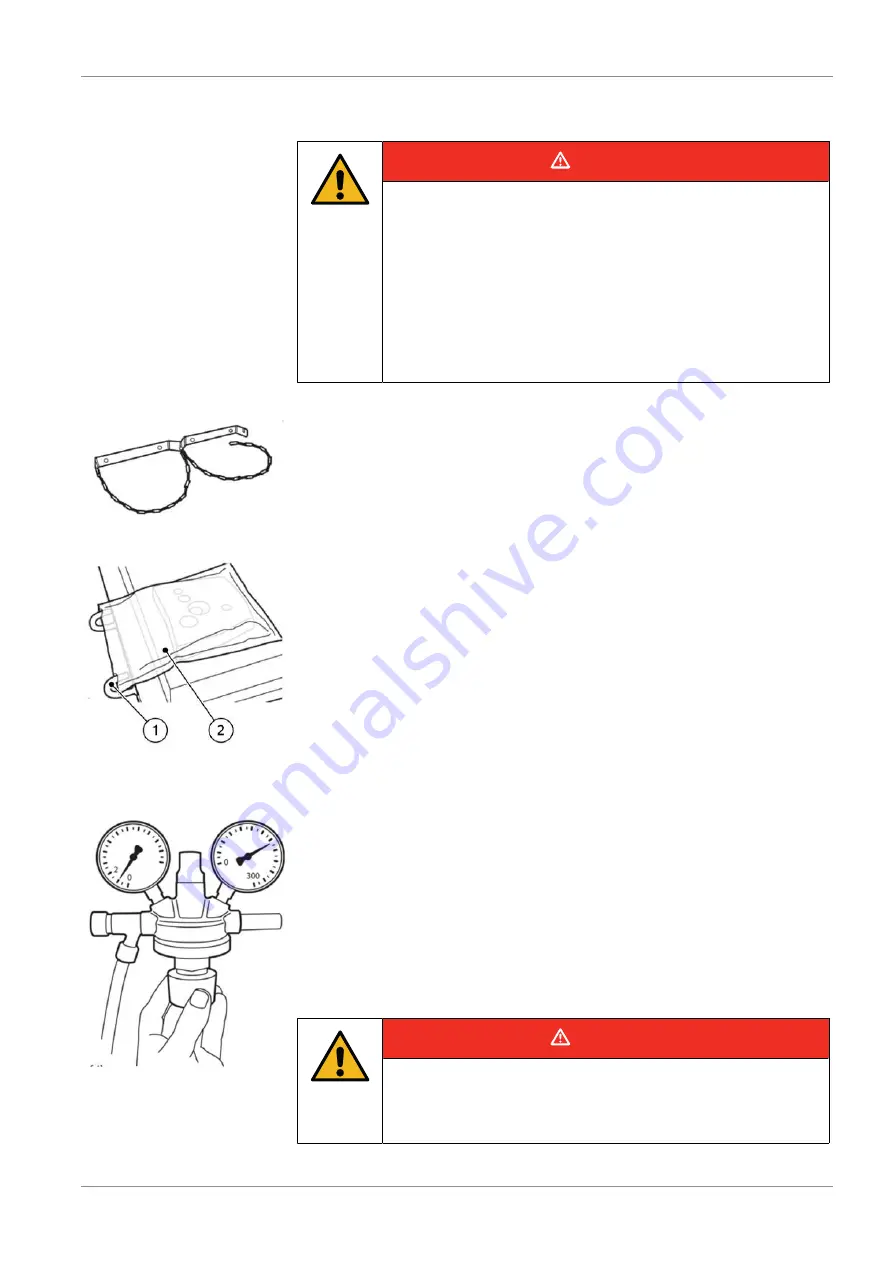

Fig. 10:

Securing the gas

cylinder

1 Set up the gas cylinder near the machine and secure it against falling with

suitable equipment.

2 Insert the gas lance into the machine.

Fig. 11:

Positioning the gas

nozzles

(1) Gas nozzles

(2) Vacuum bag

3 Align the gas nozzles (1) so that they are directed into the vacuum bag (2).

Fig. 12:

Valve fitting

4 Open the main valve on the gas cylinder.

5 Open the knurled screw on the valve fitting (to the left).

The filling pressure of the gas cylinder is displayed on the right pressure gauge.

6 Set the gassing pressure to 1 bar (displayed on the left pressure gauge).

7 In the "Inert gas" menu item of the "Programming settings" menu, set the inert

General operation of the controller CP-E3 [

ð

A higher value produces a looser packaging and a lower value produces a tighter

packaging.

DANGER

4

Food packaged with inert gas must be labelled accordingly.

4

The main tap on the gas cylinder must always be closed when

the inert gas is not being injected.