Use and maintenance manual

Longitudinal profile welding

Model: LRW-130

_______________________________________________________________________________________________________________________

P a g . 5

−

During use of the machinery and industrial use, people are subject to the risk of damage or

injury by mechanical elements in linear or gyrating movement, high voltage electric

components and static components under high temperature, due to which, during design

and construction of its equipment, ERM Engineering. has aimed to reduce and minimise

those risks by including protection devices and safety systems based on the European

Community Council Directives.

-

Installation and start-up

:

Site the machine in well ventilated places or under a fume exhaust hood.

THE FUMES PRODUCED WHEN WELDING SOME MATERIALS ARE TOXIC AND MAY

CAUSE IRRITATION OF THE RESPIRATORY TRACT.

Place the welder in such a way to simplify placement and removal of continuous belts on the

open side of the machine frame.

Allow sufficient free space for movement of material.

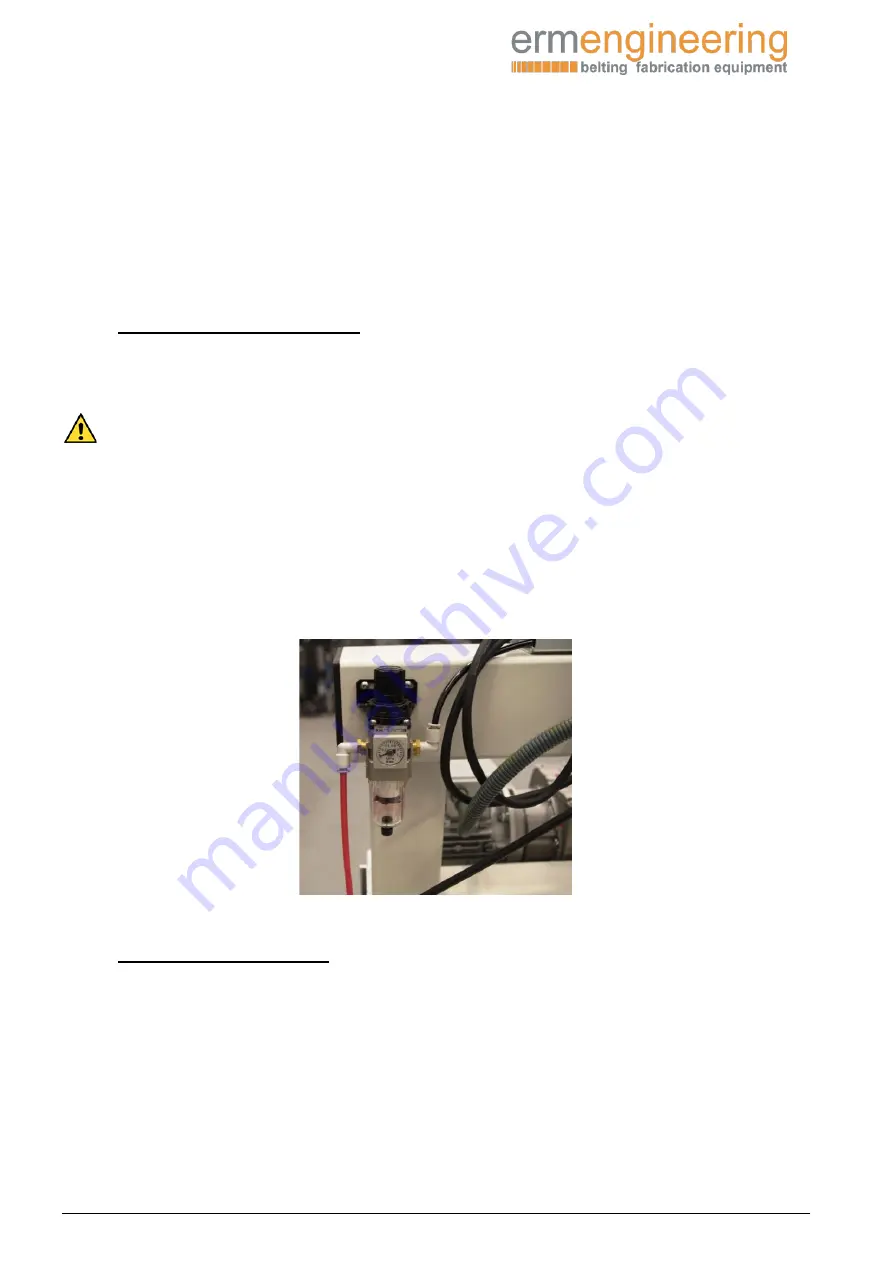

It must also be connected to a compressed air supply through the input to the pressure regulator

located on the left-hand side of the machine. Adjust the input pressure to 6 bar:

-

Electrical Connection:

Connect the machine to a suitable single-phase 2 X 230 V power supply bearing in mind the

power consumption as this depends on whether it is fitted with one or two welding heads: