M

antenimiento_1

0 v1.2.fm

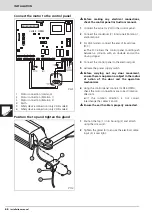

MAINTENANCE AND DIAGNOSIS OF FAILURES

VULCAN hydraulic actuator

71

4

SCRAP

n

The actuator, up until the end of its useful life,

must be dismounted at its location by an

installer who is as well qualified as the person

who completed the assembly, observing the

same precautions and safety measures. In this

manner we will avoid possible accidents and

damage to adjacent facilities.

}

The actuator must be deposited in the appropriate

containers for subsequent recycling, separating and

classifying the different materials in line with their

nature. NEVER deposit it in domestic rubbish or in

landfills which are not controlled, as this will cause

environmental damage.

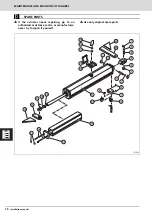

Nº.

Ref.

Denomination

Qty.

1

02A433

Axle cap

4

2

25A471

Safety washer DIN 6799_8

4

3

02A464

Fork vertical pin

1

4

02A431

Zamak fork

1

5

02A444

Fork horizontal pin

1

6

24A470

Cylindrical head screw DIN 912_M5x8 Dacromet

2

7

02A413

VULCAN gland top

1

8

03A033

Plastic gland PG11

1

9

03A094

Metallic nut PG11

1

10

Actuator

11

02A418

Spindle cover

1

12

02A410

Spindle cover top

1

13

02A414

Spindle cover top screw cap

2

14

02A416

Rods

2

15

65-N 315R-002

Support bracket 80x80x5 zinc plated

1

16

65-N315-001

Front support

1

17

02A057

Safety ring DIN 471_12x1

1

18

65-N 315-003

Hydraulic swivel joint ref. BGK-TSM-12

1

19

03A066

Hexagonal nut DIN 936_M12 zinc plated

1

20

02A437

Unlock base

1

21

02A438

Unlocking top

1

22

02A234

Washer MR424

1

23

02A441

Unlocking screw

1

24

02A443

Unlocking key

1

25A

65-N 315RL-002

Long rear support bracket

1

25B

65-N 315R-002

Support bracket 80x80x5 zinc plated

1

26A

65-N 318L-002

Long rear support

1

26B

65-N 318-002

Rear support

1

27

Faston connectors

6