Models 110X, 210X, 310X, 360X, 410X

Safety and operating instructions

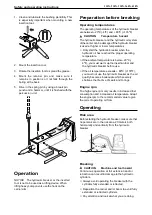

Checking and reducing the gas pressure

1. Always use the gas hose (C) and the pressure

gauge (D) when checking the gas pressure.

2. Connect the gas hose to the pressure gauge.

3. Remove the plug from the charge valve (G).

4. Press the nozzle of the gas hose into the charge

valve and read the pressure.

5. Reduce the pressure by repeatedly inserting and

removing the nozzle.

NOTICE

Only the nozzle may be used to reduce

the pressure. Never use pins, screwdrivers etc. as

these can damage the charge valve.

Every second hour

Regularly lubricate the insertion tool, the tool

retainer and the bushings.

Lubricating with a grease gun

WARNING

Hot insertion tool during

operation and a period of time after use.

►

Avoid contact with the insertion tool.

WARNING

Hot hydraulic breaker

during operation and a period of time after

use.

►

Avoid contact with the hydraulic breaker.

CAUTION

Skin eczema

Grease can cause eczema when it comes in contact

with the skin.

►

Avoid getting grease on your hands. Wash

thoroughly after contact.

1. Press the insertion tool against the piston so

that the space between the piston and the

insertion tool does not fill with grease.

2. Lubricate the insertion tool's shank plentifully

while pressing the insertion tool against the

surface to avoid filling the cavity with grease. If

the cavity is filled with grease when the hydraulic

breaker is started, the lower seals may be

damaged.

When the insertion tool shank is exposed to high

pressure and high temperatures a standard type of

grease will melt and run. To avoid this always use a

genuine insertion tool grease from your supplier.

Central lubrication system

We recommend central lubrication

carrier,

grease is pumped continuously from a lubrication

container on the carrier to the breaker when the

breaker is activated. This increases the life of the tool

bushings and insertion tools considerably.

Every day

◆

Check the tool retainer and split pin.

◆

Check that hoses, couplings and accumulator are

in a good condition.

◆

Check that bolts and connections are free from

damage and properly tightened. See tightening

torques in the spare parts list.

Summary of Contents for 110X

Page 1: ...Safety and operating instructions Hydraulic breakers Models 110X 210X 310X 360X 410X ...

Page 4: ...110X 210X 310X 360X 410X Safety and operating instructions ...

Page 25: ...Models 110X 210X 310X 360X 410X ...

Page 27: ...NEW STYLE HYDRAULIC BREAKER PARTSINFORMATION ...

Page 29: ...MINI HYDRAULIC BREAKER NEW STYLE X SERIESINFORMATION ...

Page 30: ...NOTES ...

Page 31: ...NOTES ...

Page 32: ...2012 05 No 9800 1050 01b Copyright ERSKINE ATTACHMENTS LLC ...