Summary of Contents for 2020 Series

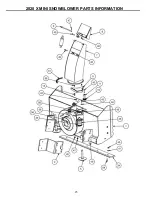

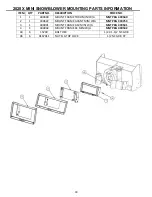

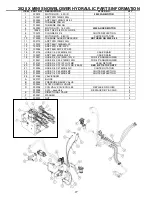

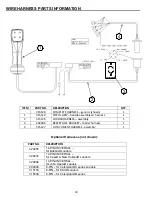

Page 23: ...23 2020 X MINI SNOWBLOWER PARTS INFORMATION ...

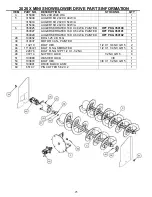

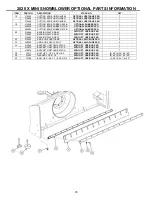

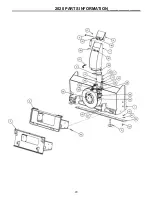

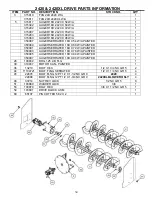

Page 29: ...29 2020 PARTS INFORMATION_______________ ...

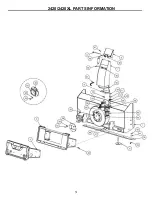

Page 31: ...31 2420 2420XL PARTS INFORMATION ...

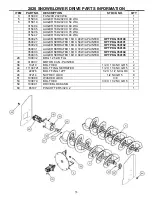

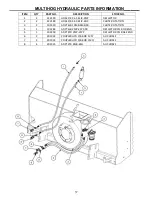

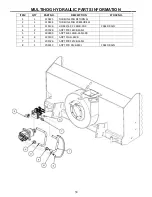

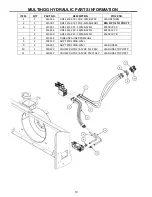

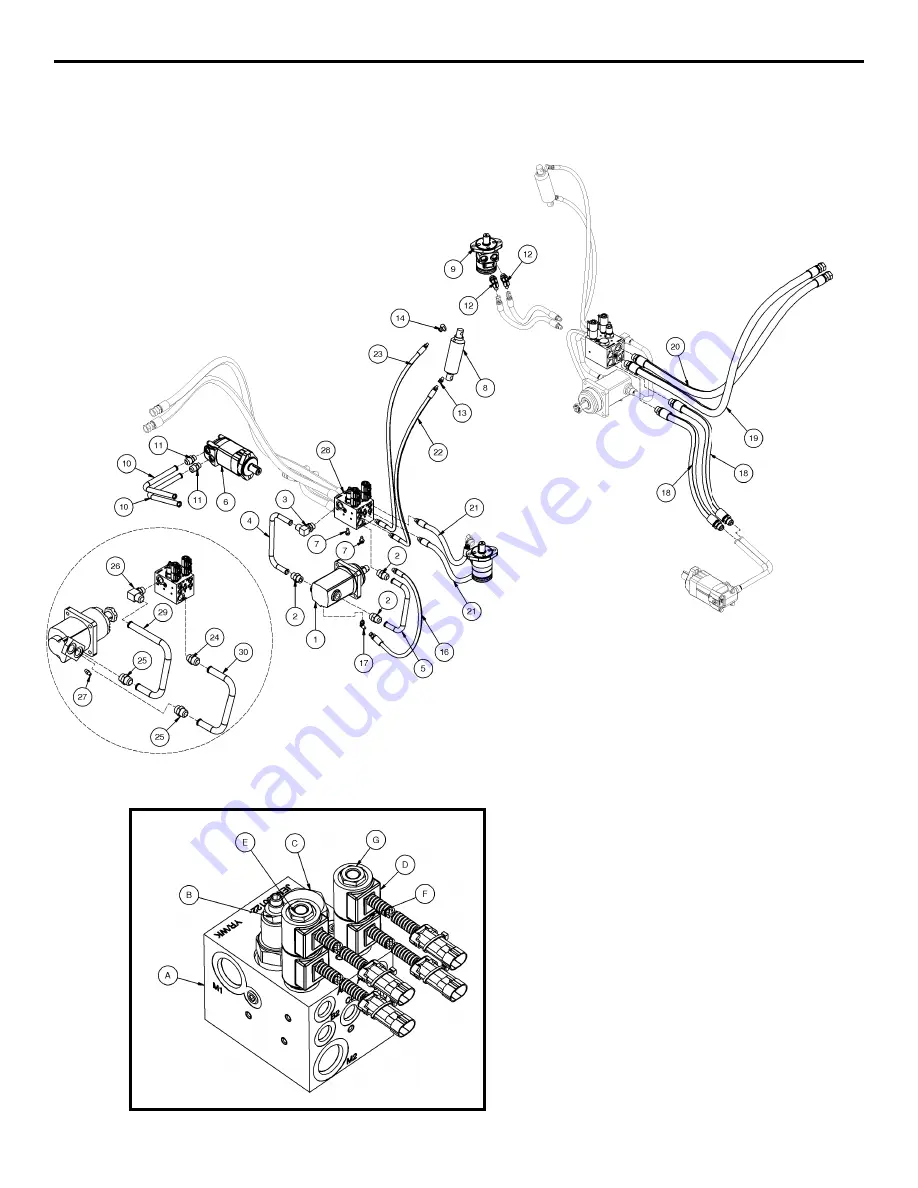

Page 36: ...36 HYDRAULIC PARTS INFORMATION ...

Page 44: ...44 P N 350099 Date Printed 11 26 2018 Erskine Attachments LLC Printed in U S A ...