15

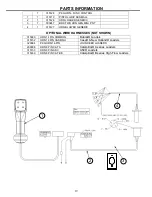

SET UP ASSEMBLY OF THE GENERIC CONTROL HANDLE HARNESS

NOTE:

If the loader is equipped with an

Attachment Control package, the appropriate

harness should be installed from the factory.

Mounting the generic control handle wire harness

will vary from loader to loader. Use these

instructions as a general guide. You may need to

drill holes to mount pieces of this harness.

Mounting hardware is not included.

1. Mount the wire harness receptacle to the

loader arm near the hydraulic quick couplers.

2. Route the wire harness back along the loader

arms and fasten with cable ties.

3. Open the rear door to access the battery

compartment. Pull the excess wire into the

engine compartment. Secure it with plastic tie-

wraps.

4. Connect the red fused wire to the positive (+)

battery terminal or to a suitable accessory wire

with a minimum rating of 5 amps.

5. Connect the black wire to the negative (-)

battery terminal or to a frame ground.

6. Connect the control handle connector to the

main harness connector.

7. Mount the control handle in a convenient

location near the operator’s station.

NOTE:

Secure the wiring harness in place

with plastic cable ties, making sure it is clear of

extra hot areas or any moving parts on the

engine or loader. Pinched, stretched, or

melted wiring harnesses are not covered under

warranty.

8. Close the rear door.

NOTE:

Be sure the harness is properly

positioned to prevent pinching when closing

the door.