Page 36

Notice G05 - 3 590 503

Issue: 11/2011 - Rev.A

ERVOR (SCA) - 6, Rue Désiré Granet - Z.I. du Val d'Argent - 95100 ARGENTEUIL FRANCE

(33) 01 34 11 50 00

(33) 01 34 11 50 10

Web : www.ervor.com - Email : info@ervor.com

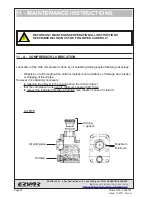

SET OF PISTON RINGS.

Pistons must be assembled with three new piston rings to run in good condition.

Before mounting cylinders make sure that each gap of the piston ring is rotated 120°

approximately in relation to the gap of the preceeding piston ring.

WEAR OF THE PISTON RING GROOVES

The efficiency of a compressor and its oil consumption depends mostly on the state of piston

rings.

Piston rings must work perpendicular to the cylinder axis and therefore the side play between the

piston ring and its groove should not be too large.

If the wear rate is reached, prepare to change the pistons and piston rings.

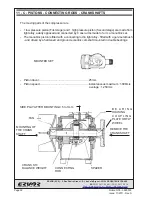

CIRCUMFERENTIAL WEARING OF PISTON RINGS

Removepiston rings. Manually place each piston ring perpendicular to the cylinder axis.

Play at cut must not exceed the play indicated below :

Piston ring diameter :

play at cut

- ANTI-LEAK ................................................................ 125mm

1.00mm

- SCRAPER ................................................................. 125mm

1.00mm

- ANTI-LEAK ................................................................ 50mm

0.60mm

- SCRAPER ................................................................. 50mm

0.70mm

OVALITY OF CYLINDERS

Disassemble cylinder heads

Remove the piston to its lowest point to free the cylinder to be checked

Check for ovality and possible scratches inside the cylinder

Change oval or scratched cylinders

Piston rings, pistons and cylinders must be checked every 4000 hours of operating.