10

SECTION 2 INSTALLATION

TABLE 2.1 Recommended Input Fuse Size

Full

Primary

Load

Input

Line

Fuse

Volts

Amperes

Size

208

52

90

230

58

90

380

36

50

400

34

50

415

32

50

460

31

40

575

25

30

2.2.2 INPUT CONDUCTOR CONNECTIONS

The unit is provided with a three conductor primary input

cable without plug. The ground lead (green) of this cable

should be connected to a reliable ground and the two

remaining wires (black and white) should be connected

to the separately fused lines of the disconnect or breaker.

See Table 2.1 for recommended fuse sizes to use in the

disconnect.

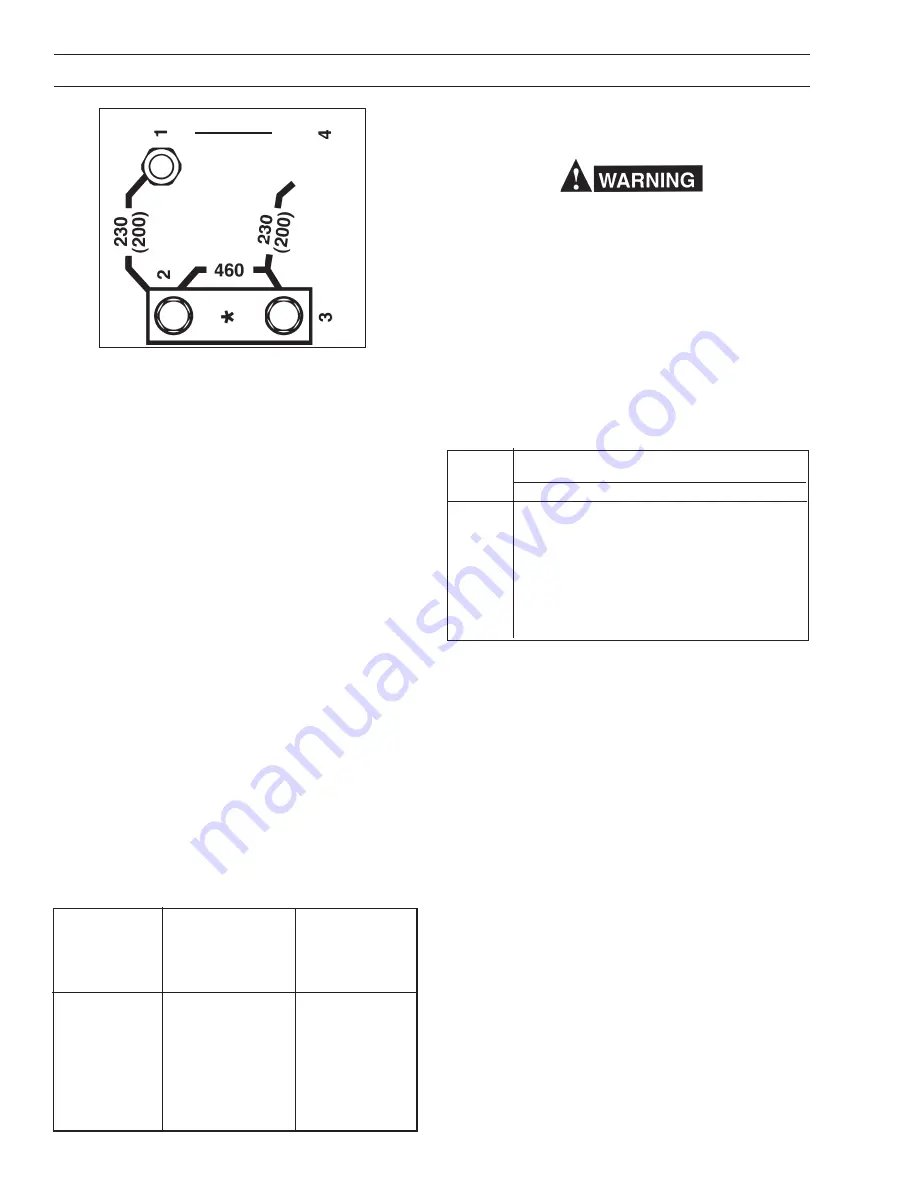

All units leave the factory with their primary electrical

input requirements internally-connected for the highest

voltage rating available (e.g.: 460-volt for the 200/230/

460-volt units; and 575-volt for the 230/460/575-volt

units).

Remove right side panel from unit and locate the input

terminal board (see Figure 2.2). If the unit is to be

operated from another input voltage, the links on the

input terminal board must be reset for that particular input

voltage. Always verify the input voltage and check the

link arrangement regardless of factory setting. The volt-

age links are setup by reconfiguring the copper link bars

to the silkscreened voltage designation for the desired

voltage.

2.3 OUTPUT WELDING CONNECTIONS

(SECONDARY)

Before making any connections to the power source

output terminals, make sure that all primary input

power to the machine is off.

The output terminals are located on the front panel

(Figure 2-3). Two output terminals are provided. The

NEGATIVE (-) terminal is located on the left side and the

POSITIVE (+) terminal is located on the right side. The

output cable connections will depend on the materials to

be welded and on the welding process desired. Table 2-

2 provides the recommended cable output sizes. Keep

welding cables as short as possible.

Table 2-2. Output Cable Sizes (Secondary)

Welding

Total Length (Feet) of

Current

Cable in Weld Circuit*

50

100

150

200

250

100

6

4

3

2

1/0

150

4

3

1

1/0

2/0

200

3

1

1/0

2/0

3/0

250

2

1/0

2/0

3/0

4/0

300

1

2/0

3/0

4/0

4/0

400

2/0

3/0

4/0

4/0

2-2/0

500

3/0

3/0

4/0

2-2/0

2-3/0

* Total cable length includes work and electrode cables. Cable size

is based on direct current, insulated copper conductors, 100-

percent duty cycle and a voltage drop of 4 or less volts. The welding

cable insulator must have a voltage rating that is high enough to

withstand the open circuit voltage of the machine.

2.4 CONTROL CONNECTIONS

Refer to Figure 2-3.

2.4.1 Wire Feeder Control

The Wire feeder control cable connection is provided by

a 19-pin receptacle (J1) located at the center of the

power source front panel. This receptacle will operate

ESAB wire feeders with 19 pin control cables including

the Mig 2E, Mig 4HD, Mobile Master 2cv and Mobile

Master 2cvcc.

2.4.2 - 42V Circuit Breaker (CB2)

The 42V resettable circuit breaker (CB2) located on the

power source front panel protects the 42 volt wire feeder/

control circuitry against over current. (Table 5-1 provides

troubleshooting information).

2.4.3 - 24V Circuit Breaker (CB1)

The 24V resettable circuit breaker located on the power

source front panel (CB1) protects the 24 volt control

circuitry against over current. (Table 5-1 provides trouble-

shooting information.

DANGER

HIGH

VOLTAGE

Figure 2.2 - Input Terminal Board

(208/230/460V Illustrated in the 460 Volt Configuration)

* Double Links