10

SLICE EXOTHERMIC CUTTING EQUIPMENT

89250840

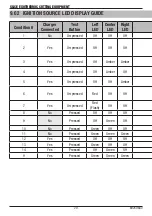

SECTION 5: CUTTING DATA

The following chart helps determine the best settings for a specific use as a result of extensive

laboratory testing of the SLICE Equipment to determine the best cutting rates. Actual cutting results

obtained in the field vary due to conditions and experience of the user. Various usages of SLICE

Equipment return various results. Adjust the settings for any use. Use the following chart as a guide.

Oxygen pressure of 80 psi (551.6 kPa) achieves the best cutting. Some operations may require higher

or lower oxygen pressures - minimum 40 psi (275.8 kPa); maximum 100 psi (689.5 kPa). Amperage

over 200 amps does not improve cutting speed.

Find the right metal and thickness. For composites or unlisted metals, locate the listed type that most

resembles the material to be cut.

NOTE!

All these cutting values are based on 1/4" (6.4 mm) diameter flux-

coated rods. Cutting rates with 1/4" (6.4 mm) bare rods are slightly

less than the values listed in the chart.

5.01 Material Cutting Rates

Material Type

Material Thickness

Length of Cut per

Inch Rod Used

Cutting Speed

in(mm)

in(cm)

in/min

cm/min

Carbon Steel

1/8 (3.2)

2.25 (5.7)

72

183

1/4 (6.4)

1.5 (3.8)

52

132

3/8 (9.5)

1.38 (3.5)

42

106

1/2 (12.7)

1.25 (3.2)

35

89

3/4 (19.1)

.75 (1.9)

22

56

Stainless

1/8 (3.2)

2.0 (5.1)

65

165

1/4 (6.4)

1.13 (2.9)

36

91

Aluminum

1/4 (6.4)

1.75 (4.4)

58

147

3/8 (9.5)

1.25 (3.2)

38

97

3/4 (19.1)

.75 (1.9)

23

58

SAMPLE SELECTIONS:

The approximate cut/inch rod x amount of cut per rod = cut per rod used

Data:

Cutting 3/8" (9.5 mm) aluminum with 1/4" (6.4 mm) fluxed rod

1.25" (3.2 cm) x 19" (48.3 cm) = 23.8" (60.5 cm). Approximate cut/min arc time = 38" (97 cm)

Data:

Cutting 1/4" (6.4 mm) carbon steel with 1/4" fluxed rod

1.5" (3.8 cm) x 19" (48.3 cm) = 28.5" (72.4 cm). Approximate cut/min arc time = 52" (132 cm)