SLICE EXOTHERMIC CUTTING EQUIPMENT

21

89250840

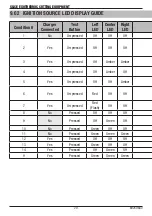

9.02 IGNITION SOURCE LED DISPLAY GUIDE

Condition #

Charger

Connected

Test

Button

Left

LED

Center

LED

Right

LED

Condition

Action

1

No

Un-pressed

Off

Off

Off

Standby

None

2

Yes

Un-pressed

Off

Off

Off

Wall power disconnected /

Internal electronics fault

Verify electrical outlet is energized.

Verify AC/DC Power Adapter Output connector is

fully inserted into DC Input socket.

Return unit for repair.

3

Yes

Un-pressed

Off

Amber

Amber

Analyzing battery (30 seconds)

Wait 30 seconds for charge status. New LED

configuration will appear.

4

Yes

Un-pressed

Off

Amber

Off

Charging battery

Wait up to 2-5 hours for a fully discharged

battery.

5

Yes

Un-pressed

Off

Off

Amber

Battery fully charged /

Trickle mode

Disconnect charger and store or keep charger

connected or use unit.

6

Yes

Un-pressed

Red

Off

Off

Thermal fuse tripped /

Battery fault /

Battery missing

Disconnect charger and wait 10 minutes for fuse

to reset / Replace battery /

Return unit for repair

7

Yes

Un-pressed

Red

(Flash)

Off

Off

Battery temperature high

Wait for unit to cool down /

Move to cooler location

8

No

Pressed

Off

Off

Off

Battery <20% capacity

Unit not recommended for use / Connect charger

9

No

Pressed

Off

Green

Off

Battery 20% to 60% capacity

Unit needs charging / Can be operated / Connect

charger

10

No

Pressed

Green

Off

Off

Battery 60% to 80% capacity

Connect charger / Unit ready for use

11

No

Pressed

Green

Green

Green

Battery >80% capacity

Unit ready for use

12

Yes

Pressed

Off

Off

Off

Battery <20% capacity

None

13

Yes

Pressed

Green

Off

Off

Battery 20% to 60% capacity

None

14

Yes

Pressed

Off

Green

Off

Battery 60% to 80% capacity

None

9

Yes

Pressed

Green

Green

Green

Battery >80% capacity

Disconnect Charger / Unit ready for use